Cheap Chinese Laser: Difference between revisions

From HacDC Wiki

(added local address for laserweb server) |

(added step-by-step instructions for software use) |

||

| Line 52: | Line 52: | ||

===Operations=== | ===Operations=== | ||

#Ensure all safety interlocks are operable by checking indicator lights | #Ensure all safety interlocks are operable by checking indicator lights | ||

##You can skip this step for now since the lights don't work | |||

#Do software stuff | |||

##Connect to LaserWeb server at [http://192.168.26.122:8000/] from HacDC network | |||

##Clear LaserWeb 4 upgrade warning popup | |||

##Click on Settings on left edge of page | |||

##Click on BACKUP at top of setting pane | |||

##Click on Restore from file | |||

##Upload [file:Laserweb-settings-backup.json] file | |||

##Click Save | |||

##Observe messages "Saved Settings" and "Please refresh page for settings to take effect" | |||

##Refresh webpage | |||

##Clear LaserWeb 4 upgrade warning popup, again | |||

##Load SVG file of cutting paths by dragging and dropping into the web browser window | |||

##Click Generate G-Code (on CAM menu) | |||

##Click Connect at the top of the webpage | |||

##If a popup appears, choose Option 1 | |||

##Click Jog on left edge of the window | |||

##Click home and observe the gantry move to the home position in the far left corner of the cutting chamber | |||

#Run program without laser powered on to observe tool path and ensure material to be cut in properly arranged in the cutting chamber | #Run program without laser powered on to observe tool path and ensure material to be cut in properly arranged in the cutting chamber | ||

##Click check outline and observe the laser move | |||

###Check that material is fully under the travel area | |||

###Check that your design is the size you expect it to be (25.4 for mm) | |||

###If the size is not right, go to the Settings page and adjust the DPI setting on the Size menu | |||

#Run program with laser powered on to cut material | #Run program with laser powered on to cut material | ||

##Click run gcode | |||

##Watch for things catching fire | |||

===Shutdown=== | ===Shutdown=== | ||

#Turn off laser chassis and master power switches | #Turn off laser chassis and master power switches | ||

Revision as of 01:31, 9 June 2017

This is the page dealing with the Cheap Chinese Laser at HacDC in the upstairs room at St. Stephen and the Incarnate church in Washington, DC. This page replaces PA LaserCutter page from some years ago. It had high ideals, but poor execution.

Introduction

HacDC has a K40, 40W, CO2, water cooled, laser for CNC cutting of various materials, aka a cheap Chinese laser. It allegedly used to work just fine, but someone decided that wasn't good enough so she ordered and halfass installed some new parts that only halfass work. After our intrepid hero, James, fullyassed the installation of the new parts, the laser still only halfass worked. Tom was railroaded into helping with the software, but even so the dynamic duo couldn't get the damn thing to work. Then one day at work, boredom struck in a meeting and James had the idea to create this wiki page to guide others through the confusion and misinformation that plagues most equipment at HacDC and often results in subpar operation. I beseech you, dear reader, to continue your edification on our topic at hand and become your own evil archvillain with laser powers. (Sharks sold separately.)

Components

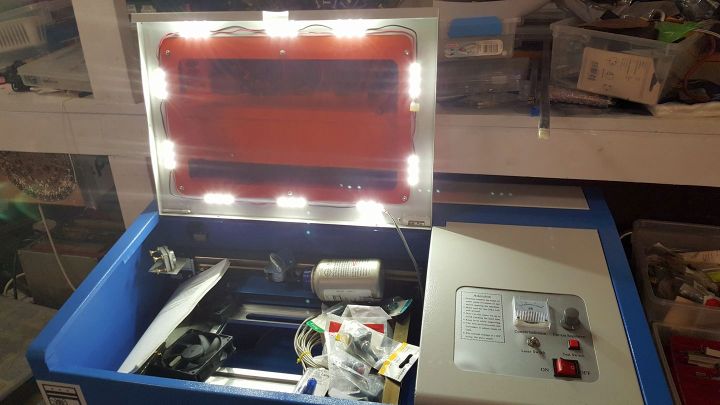

Chassis

The chassis is the laser itself, the blue metal box with 3 flip up lids. The main lid users deal with is for the cutting chamber on the left front of the machine. It includes an orange plastic window. The cutting chamber contains the transverse and longitudinal axes, aka x and y. X goes left to right, and y goes back to front. The material to be cut goes in this chamber. The second flip up lid is for the controls and power supplies chamber. This lid contains the front panel controls and indicators. There are two control boards, the Smoothie board and the K40 ACR plug-and-play board which connects the Smoothie board to the machine hardware. There are two power supplies as well, the control powersupply which is right below the control boards and the high-voltage (and I mean real high voltage, like around 15kV, not those nambypamby B.S. 120VAC "high voltage" warning labels) laser tube power supply which creates enough voltage to rip the electrons off the CO2 molecules and ionize them and cause them to emit coherent light when the electrons get back together with their matching CO2 ions. For more about this exciting process, read a science book. The third lid covers the laser tube chamber at the back of the chassis. You don't really need to mess with these last two lids unless you are modifying the equipment or troubleshooting a failure. All the lids have interlock switches and the laser will not fire if any one is open (unless you flip the override switch, in which case, it's your own darn fault for burning out your eye, as we say in Charlotte, "you did it to yourself").

Exhaust

The exhaust system sucks smoke from the laser chassis cutting chamber and sends it outside through a window. It was cobbled together using a fan and housing salvaged from a prior laser cutter and is mostly held together with zipties and metal duct tape. Seriously. I'm not kidding. Actual zipties and duct tape. (I'd like to give a shout-out to Home Depot for selling me the role of metal tape for only one cent.) If any part of the whole laser system is going to crap out, this would be a good part to bet on. It also uses 4" diameter (that's 105mm for those of you on the metric system) flexible metal clothes dryer exhaust duct to carry the exhaust gasses. There are custom-made, 3d-printed transiton pieces at the back of the laser chassis which replace the original feeble exhaust system. Read about them here

Cooling

The cooling system presently consists of a 5 gallon pail in the roller cabinet with a submersible pump. The water should be replaced with distilled. (The pump power cord got a new plug. It stays plugged in much better than the original cheap Chinese plug.) If the water doesn't flow, the laser will burnout. Sadness. The cooling system presently only works based on the heat capacity of the water in the bucket. Once the water heats up, you just need to wait for it to cool back down all by itself. You can read about other people with more sophisticated refrigerated cooling systems, but this was quick and easy, like a virgin on prom night. Julia has mentioned she's got some thermoelectric coolers in hiding for this project. We'll cross that bridge when we get everything else running first. The cooling system will have 3 interlocks: low water level, low flow, and high temperature.

Computer

This is CNC equipment. The first C is for Computer. (No, not for cookie, but we often have cookies anyway.) You need a computer with a USB port. You need computer software. I hope we can have a computer dedicated to the laser, but let's be real, that's not likely to happen. I hope Tom will fill out this section.

Cabinet

The cabinet is what the chassis sits on. The cabinet has wheels. It's made of particle board and painted white. The left door has upper and lower latches inside which hold it shut, so don't yank on it. The cabinet houses the cooling system, the 12V accessory power supply, the power strip which all the line voltage equipment plugs into: exhaust fan, cooling pump, laser chassis, 12V power supply (marginal one installed currently to power the cutting chamber accessory lights).

Safety Interlocks

Only some of these safeties are installed presently. Don't go futzing around with stuff unless you know exactly what you are doing. And tell James or Tom. For troubleshooting purposes, there is a safety override switch on the control panel (middle of three).

Ventilation

- Exhaust - If the exhaust fan isn't moving air, we don't want the laser to fire and make lots of smoke which would then fill the room

- Lens - Eventually we plan to install an air shroud nozzle around the laser lens to keep smoke from coating the lens and reducing cutting power.

Coolant

- Level - Installed

- Flow

- Temp

Doors

- Cutting Chamber - Installed

- Control Chamber - Installed

- Laser Chamber - Probably not going to install this switch because the door is in back and control panel space is at a premium

- Cabinet - Probably not going to install this switch because there's not much harm in the cabinet and control panel space is at a premium

Workflow

Prestart

- Come up with design

- Create SVG using software like Inkscape

- Upload SVG to computer

- Convert SVG to toolpath using software like Laser Draw

Startup

- Roll cabinet out from under shelf

- Get extension cord out of cabinet and plug laser into extension cord and extension cord into live receptacle

- Turn on laser master power switch

- Close cabinet door

- Load material to be cut in laser cabinet

- Shut lid on cutting chamber

- Turn on laser cabinet power switch

Operations

- Ensure all safety interlocks are operable by checking indicator lights

- You can skip this step for now since the lights don't work

- Do software stuff

- Connect to LaserWeb server at [1] from HacDC network

- Clear LaserWeb 4 upgrade warning popup

- Click on Settings on left edge of page

- Click on BACKUP at top of setting pane

- Click on Restore from file

- Upload [file:Laserweb-settings-backup.json] file

- Click Save

- Observe messages "Saved Settings" and "Please refresh page for settings to take effect"

- Refresh webpage

- Clear LaserWeb 4 upgrade warning popup, again

- Load SVG file of cutting paths by dragging and dropping into the web browser window

- Click Generate G-Code (on CAM menu)

- Click Connect at the top of the webpage

- If a popup appears, choose Option 1

- Click Jog on left edge of the window

- Click home and observe the gantry move to the home position in the far left corner of the cutting chamber

- Run program without laser powered on to observe tool path and ensure material to be cut in properly arranged in the cutting chamber

- Click check outline and observe the laser move

- Check that material is fully under the travel area

- Check that your design is the size you expect it to be (25.4 for mm)

- If the size is not right, go to the Settings page and adjust the DPI setting on the Size menu

- Click check outline and observe the laser move

- Run program with laser powered on to cut material

- Click run gcode

- Watch for things catching fire

Shutdown

- Turn off laser chassis and master power switches

- Unplug laser and extension cord

- Coilup and store extension cord

- Shut cabinet door

- Roll cabinet back under the shelf

- Continue with your evil plans for world domination

Custom Wiring

Julia had some LED strips she wanted installed. We succeeded. The illuminate when the main power is turned on.

They are white LEDs but the orange laser viewing window colors them.

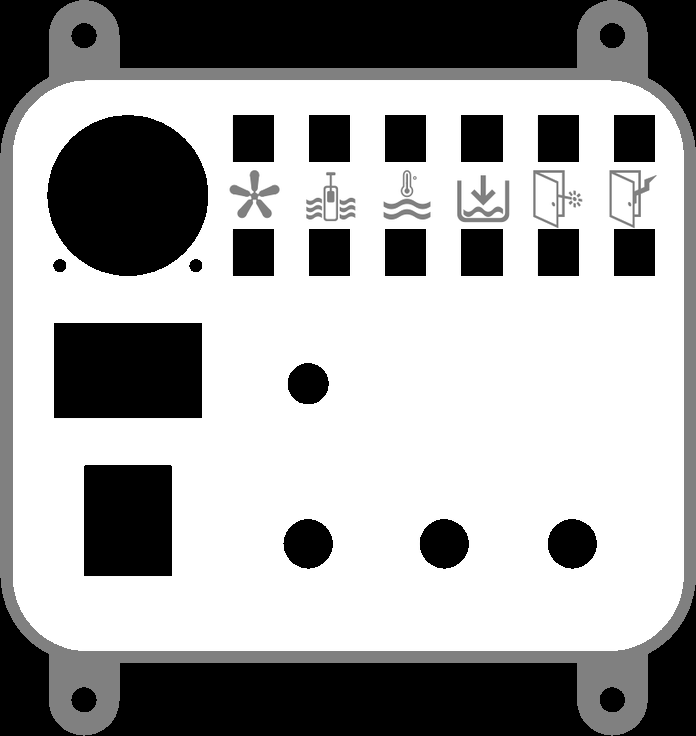

Sully really likes relays and discrete, analogue circuits, so he jimmied up a bunch of stuff to make it less likely for you to poke your eye out or burn out the laser. The laser power supply from the factory takes input from 3 front panel controls: off-on laser switch, momentary-on laser switch, power control potentiometer knob. The off-on switch was a cheap latching push button which was connected to the leftmost two terminals of the 6 terminal plug with black wires. It was replaced with an off-on, metal, toggle switch on 3-23-17. The middle two terminals of the block connect to the momentary on push button switch on the front panel which causes the laser to fire (when the left two terminals are shorted together by the toggle switch). The right 3 terminals (which overlap with the right center terminal going to the push button switch) connect to the front panel potentiometer which controls the laser current. Do not turn the knob to full clockwise, because increasing the laser firing current past a certain point doesn't provide any benefit and just reduces the tube lifespan. The plan is to parallelize the push button firing switch with a solid-state relay controlled directly by the Smoothie board and bypassing the K40 ACR board (which was supposed to make the Smoothie board plug-and-play, but as mentioned earlier did a halfassed job). The potentiometer will be connected to a 3PDT switch for computerized or manual power level control. A PWM to DC circuit will do the automatic control and the original pot will remain for the manual control. The safety interlocks are basically a whole bunch of microswitches in series so if any one of them gets tripped the left two pins of the power supply 6 pin connector won't be shorted together and the laser won't fire. There's also a plan to have lights illuminate to show which safeties are operating properly or tripped. Plus indicator lights are cool. And for the remaining manual firing switches we plan on getting those flip-up red covers like in those military movies where they're firing nuclear missiles and stuff like that. These would aid in troubleshooting, and look really cool, even if they are kinda spendy. Man, this is really turning into a wall of text. Someone should do something about this sometime. Anyway, schematic drawings would go here, or links to them would go here.

Terminal Block Connections

- Cutting chamber door safety switch - common

- Cutting chamber door safety switch - n.o.

- Cutting chamber door safety switch - n.c.

- Control chamber door safety switch - common

- Control chamber door safety switch - n.o.

- Control chamber door safety switch - n.c.

- Cooling water level float safety switch - common

- Cooling water level float safety switch - n.o.

- Cooling water level float safety switch - n.c.

- Laser fire switch 1

- Laser fire switch 2 - one of these is the same as power level GND (immediately below)

- Laser power supply power level control potentiometer GND

- Auto power control voltage divided between +V and GND - connects to auto-hand control panel switch and to PWM-DC converter circuit output

- Laser power supply power level control potentiometer +V

Custom Parts

Images of custom parts like the exhaust nozzles and eventually a new control panel and source files for 3d printed or laser cut parts can go here.

This image is colored for 3d printing using it as a height map: black=0mm, gray=1mm, white=2mm. 174mm wide, 184mm tall. The SVG file was created by a Ruby program to modularize the positions and sizes of cutouts for switches, nobs, lamps, etc.

Bill of Materials, a.k.a. Donation Wishlist, and Hardware Store Shopping List

- Laser goggles

- USB A-B cord, i.e. printer cable, which doesn't suck

- Solid state relays -- we used [2] this one. --This should move to custom parts and off the wishlist (JS 4-20).

- Stuff to cut

- 1/8" Baltic birch plywood

- Plastic sheets, e.g. acrylic

- Masonite?

- Cabinet reinforcements

- dimensional lumber, e.g. 2x4, 2x2, 1x3

- unidirectional casters

- Cooling system stuff

- Distilled water

- Float switch

- Thermocouple or thermistor/RTD temperature sensor probe

- Radiator and fans

- Solidstate heat pump

- Working water fountain chiller (for future use on the 100W downstairs)

- PLC/Microcontroller with A/D inputs for temperature probe conditioning and temp display (advanced task)

- Green connectors for smoothieboard and laser powersupply [3]

To-Do Tasks

- Airflow switch housing

- manufacture

- install

- Coolant interlocks

- Flow sensor

- design

- manufacture

- install

- Temp sensor

- design

- manufacture

- install

- Flow sensor

- Door switches

- Cabinet door

- Laser tube chamber door

- Chassis wiring

- Wire up the safety switches as they are installed

- Draw a wiring diagram of custom components

- CNC firing control - This svg file can be used to test run the laser: Laser circle test

- find firing signal on Smoothie board

- in the config you specify this with laser_module_ttl_pin

- determine relay requirements

- purchase and receive relay

- install firing relay

- software

- determine best software to use

- develop workflows for various programs and operating systems

- update this page to explain the above

- We're gonna use Laserweb I think so setup a RasPi or something as a Laserweb server.

Completed Tasks

If you do work on the laser, please record it here.

| Task | Fixer | Date | Notes |

|---|---|---|---|

| Create Wiki page | James | 3/24/2017 | Ongoing updates needed |

| Install operational exhaust system | James | 2/2017 | Still needs interlocks |

| Install cooling system | James | 2/2017 | Air cooling or refrigeration could be added |

| Connect control power supply to switched mains | James | 3/2017 | Done |

| Get x and y axis movements working | Tom | 3/2017 | Firing still needs to be fixed |

| Replaced cooling pump power cord plug | James | 3/26/2017 | |

| Installed door closure bolts on left cabinet door | James | 3/26/2017 | |

| Installed cutting chamber illumination LEDs and 12VDC powersupply | James | 3/26/2017 | |

| Control + interlock circuits design/brainstorm session | James + Tom | 3/27/2017 | See webpages below for Smothieboard help |

| Mocked up and tested control circuit for PWM from smoothieboard | James + Tom | 3/27/2017 | http://smoothieware.org/laser-cutter-guide |

| Scoped out various pins on the smoothieboard to find PWM out | James + Tom | 3/27/2017 | http://smoothieware.org/smoothieboard-v1 |

| Removed control panel | James | 3/30/17 | Don't mess with nothing until a new one gets installed! |

| Tried to 3d print a new control panel | James | 4/2/17 | Lulzbot Taz either didn't extrude or made bird poop. :( It's too bad we don't have a working laser cutter. |

| Adjusted program size parameters based on failed print and added ammeter mounting screw holes to control panel design | James | 4/11/17 | Still need to upload new SVG here and print it |

| Ordered self adhesive cable tie mounting squares and SSR for PWM-> DC | Tom | 4/11/17 | Delivery expected Thursday |

| Design 3d-printed mounting bracket/clip to hold switches for door interlocks | James + Tom | 4/15/17 | Impromptu Saturday night productivity session. |

| Design, breadboard and test PWM circuit with solid state relay and newly determined time constant | James + Tom | 4/15/17 | Impromptu Saturday night productivity session. |

| Uploaded exhaust nozzle and exhaust flow switch scad files | James | 4/20/17 | Flow switch needs printing and Tom's nacelle needs dimension tweeking. |

| Tried printing control panel on the Ultimaker2 | James | 4/25/17 | Print failed twice, but third time looked good before I left. |

| Installed control panel 3d printed on Tuesday | James | 4/27/17 | Controls and indicators are installed but not operational, yet. It looks sweet! Could be thicker, maybe 4mm. Dimensions could use tweeking too: toggle switches moved down, corner radii reduced,... |

| Uploaded source code and stl for water level float switch and for terminal block holders. Installed v5 of door switch holder and soldered wires to switches. | James | 5/1/17 | Still need to print float switch parts and terminal block holders. New parts fit well. A very productive day overall. |

| Installed terminal block with manually modified v1 terminal block holder parts. Wired up cutting chamber and control chamber door safety switches. Connected laser power supply wiring to new control panel switches. | James | 5/4/17 | Need to adjust terminal block holder dimensions and reprint. |

| Uploaded v2 source code and stl for terminal block holder. | James | 5/5/17 | Need to print float switch parts and terminal block holders. |

| Printed and installed new terminal block holders (v2). Printed new air flow switch and water level float switch head and base. Remodeled exhaust header. | James | 5/6/17 | Holders fit great. Base, not so much. |

| Reprinted water level float switch base. Investigated PWM output from Smoothieboard. | James + Tom | 5/7/17 | Pin 4.2 and GND work for PWM signal. PWM to DC breadboard isn't working. Laser power supply 5V circuit for safety switches doesn't have enough current to illuminate the trouble lamps on front panel. |

| Install float switch. | James | 5/11/17 | Not seeming to function as of 5/14 - remains conductive even when open? |

| Successful CNC laser firing on circle laser test. | James + Tom | 5/14/17 | Some kind of beam splitting or 2-layer reflection is going on. PWM out can be set using laser_module_pwm_pin in smoothieboard config. |

| Setup the auto-man power level control switch. General stuff. | James + Tom | 5/28/17 | We've got some stray AC current in the case. |

| Installed RasPI as webhost. Replaced USB cable. | James + Tom | 6/4/17 | Laserweb server, from HacDC network |

| Test cut Pepe the frog on opaque acrylic with painters tape mask. | James + Andrew | 6/5/17 | Auto fire signal still isn't working. |

| Added circuitry to breadboard to automate the firing signal. | James | 6/6/17 | Will test on Thursday. |