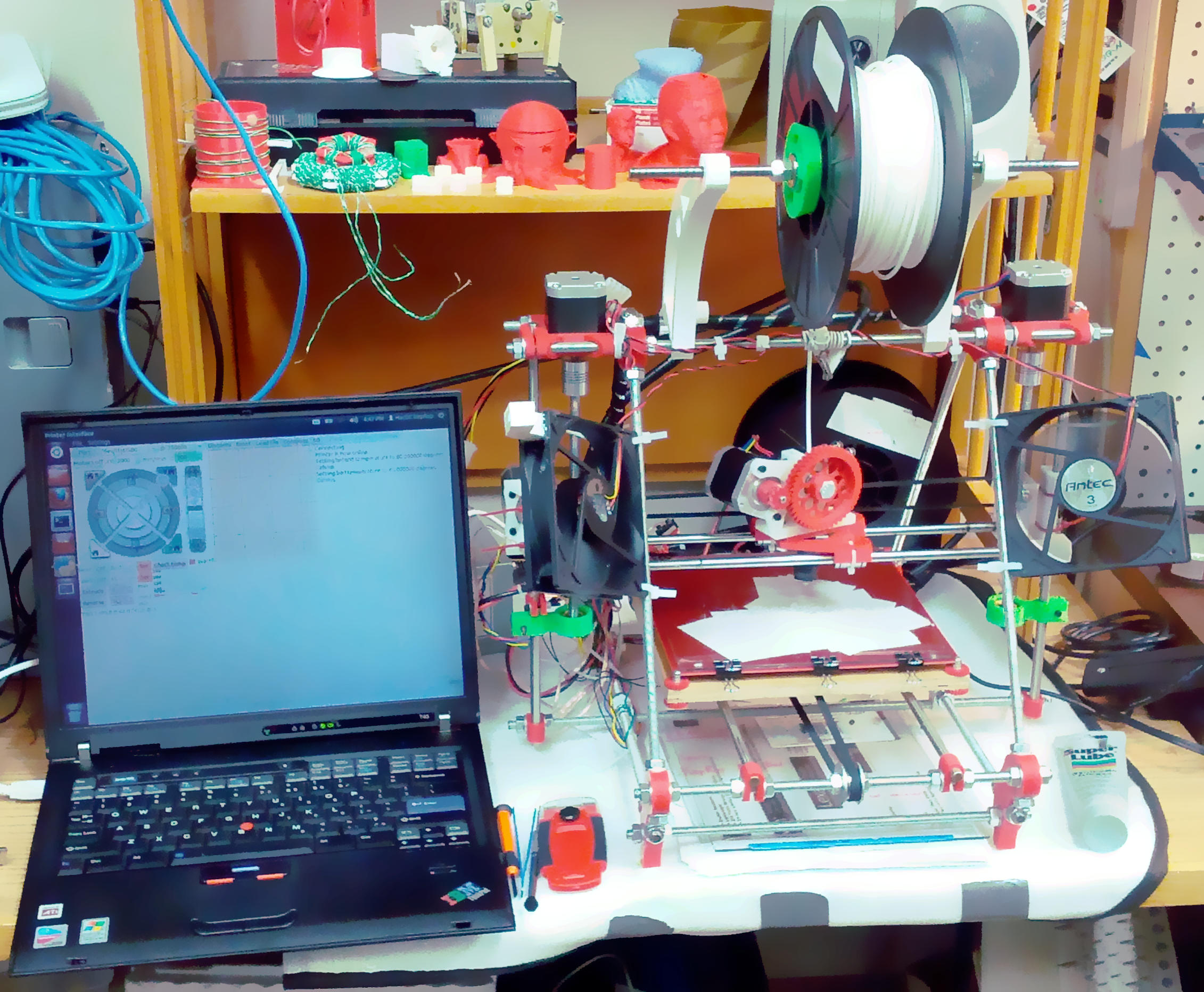

Prusa Mendel Documentation

From HacDC Wiki

This is the page on how to use the newly built Prusa Mendel (iteration 2). A PC has been dedicated to run it, below you will find the toolchain used to run it and other details that you may find useful.

Current Machine Status

Minor Repairs Needed

Workflow

CAD/Thingiverse -> Netfabb -> STL -> Slic3r -> Pronterface -> PRINT!

See operation section for a tutorial.

- CAD

- FreeCAD (free, open source) and SolidWorks (expensive, some extra features) offer intuitive sketch and constraint based modeling.

- OpenSCAD uses programming code to describe 3D models.

- And in case you don't want to model anything and simply want to print stuff, go to Thingiverse.

- Netfabb

- software for checking the "3D printability" of the model you created. Go to Netfabb and download the Studio Basic option. You can also simply use their cloud offering and have a repaired model emailed back to you.

- if your model has issues, run the repair function with default settings and see if that remedies the issues. The repair function can be used by clicking the "first aid" symbol found at the far right on the tool bar.

- STL

- current format for 3D printing (AMF is coming around the corner).

- at this point, your file should be patched up and ready to print.

- Slic3r

- software for creating 3d printing toolpaths

- precompiled binaries can be had from Slic3r.org or be built built from github.

- use the profiles already generated for best results.

- Pronterface

- GUI for controlling the Prusa.

- where you will connect to the printer, home, warm up and send print jobs from.

- can be built from github or download precompiled binaries for Windows/Mac here.

- preview G-Code generated by Slic3r.

- File is good to go, toolpaths are generated, time to let the robot do what it does best, PRINT!

Materials

- PLA - Polylactic Acid

- Extremely ecologically friendly, made from corn starch, smells like waffles/syrup while printing.

- Needs a fan for parts with overhang/bridging.

- Low operating temperature (160C-200C).

- ABS

- UNSUPPORTED, WILL DAMAGE PRINTER. Used by old makerbot.

Maintenance

Safety - ALWAYS CHECK

FIRE HAZARDS

- Power Supply. NEVER leave ATX power supply on after leaving HacDC, it gets hot.

- Temperature Sensor. NEVER heat the bed without temperature sensor in place.

Machine Damage

- Loose wires. Short circuits can cause severe damage.

- Lose bolts. In particular, check the endstop bolts.

- X/Y endstops. Manually push X/Y axes to test the switches.

- Z-axis endstop. Visually check that it will trigger before severe crash into print bed.

- Extruder gears. Must mesh closely, or will chip. Fortunately, these are easily replaced/repaired.

Malfunction

- Grease smooth rods and Z-Axis threaded rod if axes show signs of binding.

- Only grease with PTFE SuperLube, kept at HacDC next to RepRap.

- Floss the hobbed bolt in the extruder.

- Tighten timing belts if necessary.

- Replace linear bearings if they are grinding, slipping laterally, or otherwise ruined.

Bed Cleaning

- Polycarbonate bed should be kept flat, without excessive protrusions. Scrape excess plastic off, and trim deep cuts.

- Bare blass bed must be clean, but not too clean. Best practice seems to be wiping with a paper towel, and then gently brushing dry fingers across the glass.

- Blue paper tape may be used on glass or polycarbonate bed. Surface adhesion is more predictable. Downside is the need to occasionally replace the paper tape.

Print Depth

- First-layer depth. For polycarbonate and paper tape beds, this must be <0.4mm below the bed surface. For bare glass bed, exactly 0.2mm above the bed surface is required. These distances can be measured in pronterface, by homing the Z-axis, then commanding Z-axis movement in 0.1mm increments.

- Z-axis height. Z-axis endstop position sets depth for entire bed.

- Z-axis level. The dual threaded rods must be kept aligned.

- Bed leveling. Place Z-axis just above bed, then move X/Y axes. Place thin paper strips under bed until level.

Replacing filament/changing spools

- Turn on the printer, open pronterface, and connect to the printer (instructions above)

- If there is filament sticking out of the top of the extruder, you'll need to remove it

- Set the hotend temperature (175-185 degrees Celsius for PLA)

- When extruder is warmed up, raise the extruder (+z axis) so it's not touching the bed

- Click the reverse button while gently pulling upwards on the filament you wish to remove

- Continue gently pulling and pressing reverse until the remaining filament is drawn out from the top of the extruder housing

- Once the filament has been removed, replace the spool

- Feed the new filament into the appropriate hole in the extruder housing

- Gently press down on the filament while clicking "extrude" in pronterface. The extruder should grab the filament as you feed it

- Repeat the previous step until you see the new material being extruded from the tip

Tips

- Some problems may be ambient temperature related. When the room is 52F (11C), plastic curling, extruder jams, and Z-axis endstop malfunction are more likely. Placing a space heater on medium heat (~750W) at least four feet from the RepRap helps. Usual concerns about space heaters apply, be safe.

- Leave fans at "Low" setting. Higher settings are rarely helpful, and usually blow the plastic away.

- Warping or excessive adhesion on polycarbonate bed may be improved with paper tape and temperatures >45C.

Operation

- Emergency Stop. Be ready to unplug USB cable when beginning X/Y/Z motion.

- Go through the maintenance list as necessary, especially the safety section.

- Check which bed you are using. Glass with paper tape recommended.

- Turn on power strip. Switch on the ATX PSU behind the machine. Large fans should start spinning.

- Load an STL model onto the dedicated laptop for printing. If you haven't made one, download one from Thingiverse.

- Clean the STL model. Load file in nefabb, click the red "+", "Automatic repair", "Default repair", "Apply repair", "Yes" - remove old part. Finally, export part as STL, repairing more errors if prompted.

- Open Slic3r. Drag your STL file from a file manager onto the "Drag your objects here" box in Slic3r.

- "Print settings: Cheap" "Filament: Solid" "Printer: HacDC" Use these settings to print fast, with minimal plastic, high strength, and reasonable droop on short bridges.

- Export G-Code in Slic3r. This can take a while, so proceed to the next steps without waiting.

- Open pronterface.

- Connect to the printer. Check box "Watch" to see temperature readings. You should see about 20C on all temperature sensors, and basic stats in the console window.

- Set heated bed to 45C.

- Wait for Slic3r to finish. Click "Load" and load the G-Code file you have created. A preview of the first layer should appear in the middle of Pronterface. You can click on the preview and walk through the layers by holding shift and scrolling on the trackpad. In the console, a time estimate for the print should also appear.

- Set extrusion heater to 185C.

- Extrusion rate in pronterface should be 150mm/min or less. Always <50mm/min if <185C temperature.

- Wait for it to hit temp and prime it. You can do this by either manually turning the large extruder gear or pressing the "Extrude" button. Do so until there is a nice and steady flow.

- Once all temps are hit and stable, file is loaded and extruder is primed...you can now hit print!

- Sit back and watch as the printer homes itself and sprints off to print your file!

Please Avoid

You are adding to the workload on a shared machine. Please be gentle.

- NEVER leave ATX power supply on after leaving HacDC, it gets hot.

- NEVER heat the bed without temperature sensor in place.

- Printing faster than 65mm/s without acceleration incurs excessive stress and more frequent maintenance.

- Manually moving Z-axis threaded rods delevels machine, which takes time to fix.

- Raw polycarbonate bed above 45C will have extremely strong adhesion. Even if you can remove your part, you will likely warp the bed doing so.

- Paper/kapton tape should only be applied to top side of the glass bed, same as the front edge guard tape.

Slic3r Settings

Print Settings

Cheap

Default Fast, minimum material use. Virtually all parts will not benefit from the other settings.

Cautious

Same as cheap, reduced speed. Some artistic parts with thin walls will benefit.

Thin

Very low speed, nominal layer height, extra perimeters. Intended for extreme non-structural (artistic) components.

Robust

Solid, faithful parts. Use only for engineering parts requiring extreme strength (>10kg force across a few square millimeters). Voraciously consumes plastic, please use only if warranted.

FilamentSettings

Solid

185C Extrusion Temperature. Maximizes strength. Bridges >~3mm will droop badly.

Compromise

175C Extrusion Temperature. Balances strength with better bridging.

BridgeSafe

167C Extrusion Temperature. Can pass the bridge test. Reduced mechanical strength, best for artistic parts.

Printer Settings

Leave at "HacDC" unless you feel they need debugging.

Advanced

Entire software load used on dedicated laptop available at github. With these files, one can use their own computer to control the reprap.

Credits

| digifab | Constructed and donated working PrusaMendel Reprap. |

| juri | Consultation on maintenance and multiple emergency repairs. |

- Several HacDC members for finance.

- Others.

Technical Specs

This Prusa is fitted with the following:

- Melzi - loaded with the latest Marlin firmware (as of 9/1/2012)

- 12V 30A PSU

- Makergear 0.35mm for 3mm filament hot end

- LM8UUs

- GT2 (2mm) belting and pulleys (5mm bore, 20 tooth)

- 100K Thermistors (extruder an heated bed)

For FW reference on steps per axis: (80, 80, 2560, 666.67) {X, Y, Z, E}, this is also assuming 1/16th microstepping.

To Do

- Tune trimpots on motor drivers

- More Cable Management (Spiral wrap loose wires and ziptie down)

- Add some example printouts to the wiki.

- Print spare parts.

- Support KISSlicer for improved dimension accuracy in some cases.

- Experiment further with extrusion width settings, particularly perimeter widths.

- Thermal fuse print bed PCB heater for safety.

Known Bugs

- Model holes will print the wrong size. The proper way to manage this is by keeping about 1.5mm per wall or 3mm diameter clearance in CAD models.

Additional Resources

- "Slic3r is Nicer - Part 1 - Settings and Extruder Calibration" http://richrap.blogspot.co.uk/2012/01/slic3r-is-nicer-part-1-settings-and.html

- A guide to calibrating and using slic3r: https://github.com/alexrj/Slic3r/wiki/Calibration