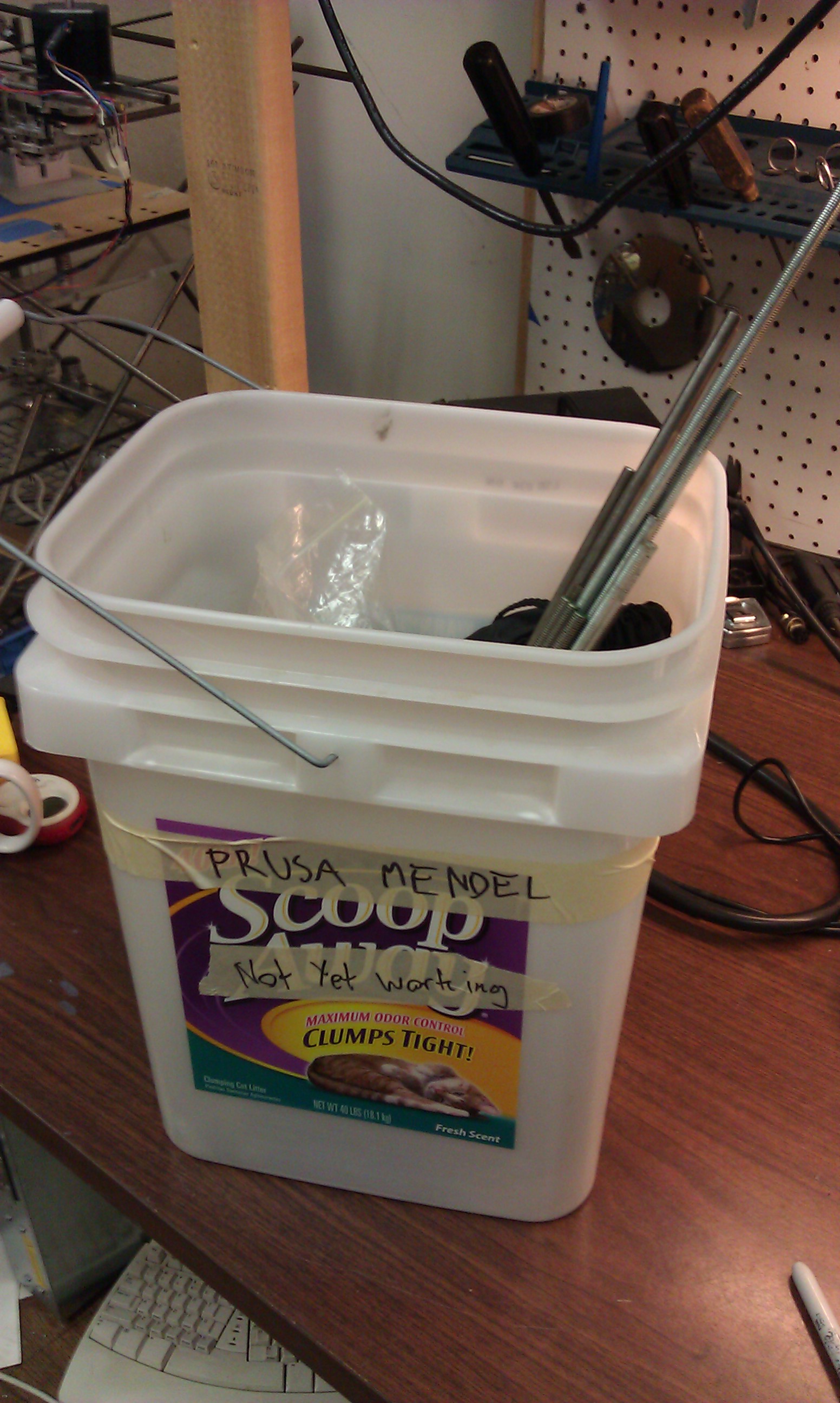

Prusa Mendel Documentation

From HacDC Wiki

A new reprap printer will built along the lines of the Prusa Mendel. You can find details of the Prusa design at the Prusa Mendel page on the reprap wiki, or you can view the sources for the Prusa at github

Intro

Having another 3d printer in the space will allow us to always have a working machine and to use one machine to help fix another if there are problems. It will also enable several people to print things out at the same time. The goal is to document this build so others can make their own printer following our documentation.

Status

Turns out the Imperial 5/16" washers are not a workable replacement for M8 washers, so we need to get those before the frame construction can begin. Also, we're still waiting on electronics from John.

Materials for the build

BOM for Prusa Mendel

| Quantity | Description | Type | Comments |

|---|---|---|---|

| 83 | M8 nut | Fastener | READY |

| 93 | M8 washer | Fastener | NEEDED (the imperial 5/16" ones aren't gonna work) |

| 6 | M8×30 mudguard / fender washers | Fastener | READY |

| 2 | M4×20 bolt | Fastener | (John) / or use M5x20 |

| 2 | M4 nut | Fastener | (John) / or use M5 |

| 2 | M4 washer | Fastener | (John) / or use M5 |

| 22 | M3×10 bolt | Fastener | READY |

| 8 | M3×20 bolt | Fastener | (John) / cut down 25mm or use as is |

| 8 | M3×25 bolt | Fastener | READY |

| 4 | M3×40 bolt | Fastener | (John) / cut down 50mm or use 35mm |

| 70 | M3 washer | Fastener | READY |

| 40 | M3 nut | Fastener | READY |

| 2 | M3 grub screw / set screw | Fastener | (John) / will the M3 x 8 in the space work? |

| 3 | 608 roller skate / inline skate / skateboard bearing | Bearings | READY |

| 4 | ballpoint pen springs | Spring | READY |

| 6 | M8×370mm | Threaded rod | 3 per side - READY (Thanks Mark!) |

| 4 | M8×294mm | Threaded rod | front / rear - READY 4 x 340 (Needs cutting) |

| 3 | M8×440mm | Threaded rod | top / bottom - READY |

| 2 | M8×210mm | Threaded rod | Z-leadscrew - READY 2 x 300 (Needs cutting) |

| 1 | M8×50mm | Threaded rod | or bolt for X idler - READY |

| 2 | 8mm×420mm | Smooth rod | X-bar - READY |

| 2 | 8mm×406mm | Smooth rod | Y-bar - READY |

| 2 | 8mm×350mm | Smooth rod | Z-bar - READY |

| 1 | 225mm×225mm print top plate | Thick Sheet | (space) |

| 1 | 140mm×225mm print bottom plate | Thick Sheet | space |

| 1 | 840mm×5mm T5 pitch timing belt | Belt | READY |

| 1 | 1380mm×5mm T5 pitch timing belt | Belt | READY |

| 5 | NEMA 17 bipolar stepper motor | Stepper | John |

| 50 | small cable binder / ziptie | Misc | READY |

| 1 | Wade's Geared Extruder | (John) | |

| 1 | Electronics + endstops | gen3 from John or Tiny G from Alden | |

| 1 | Printed parts | READY |

John

1x gen3 mobo 2x gen3 EC 5x steppers 4x stepper controllers (we'll have to pull these from the cupcake and have the cupcake use the mbi ones) 1x p4ac 4 axis stepper controller carrier board (we'll have to pull this from the cupcake too) 1x wade's extruder (assembled and working) 1x 36mm brass barrel 1x 0.5mm mbi nozzle 1x 0.5mm makergear bighead nozzle Insulator materials (have to make and document on lathe) nuts/bolts/washers - I have tons plywood/mdf for build platform

Heated Build Platform

If we want it, can get away with some other hacks if we want, or leave it out altogether.

Offers

Alden has a Tiny G board... this is attractive