Category:Cube

From HacDC Wiki

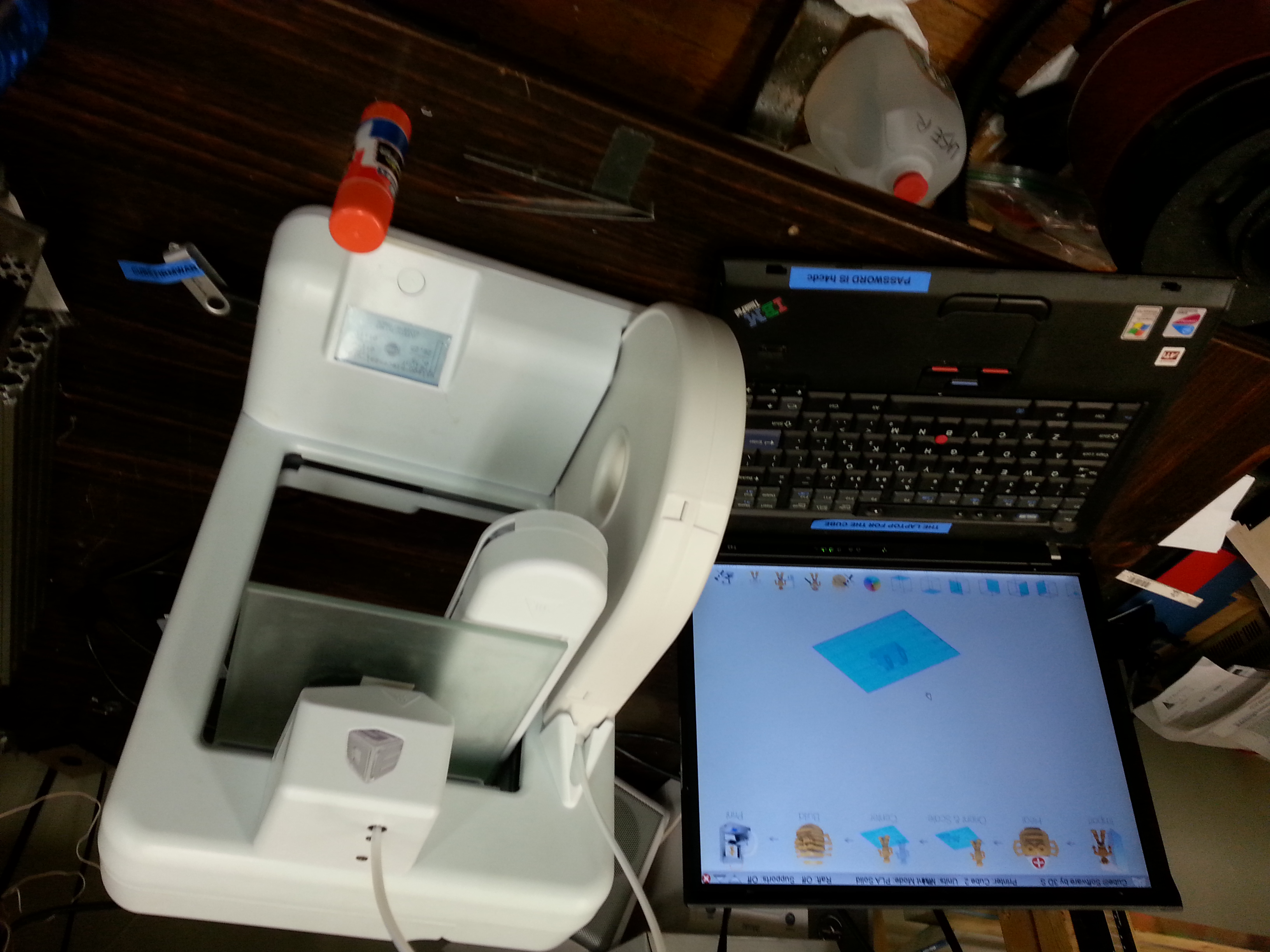

HacDC's Cube 3D Printer.

Current Machine Status

Operational

General Info

Model: 3D Systems Cube 2ND Generation

Printing Procedures

Instructions are mostly complete but there are still gaps. If this is your 1st print with this machine you may want to ask one of the 3D printer folks for help (We're usually around on Thursday evenings).--Nostromo (talk) 15:44, 11 February 2015 (PST)

3D File Preparation

The cube uses proprietary slicer software to convert a ".stl" file to a ".cube" file which is what the cube printer understands.

- Power on the Laptop labelled "THE LAPTOP FOR THE CUBE"

- Open the "Cube Software"

- Import your .stl file

- Settings

- Raft: Isn't needed as the bed is pretty level

- Print Mode

- Hollow: (Quick) The software will print the walls of your model but put only enough infill to keep the model together. Not to be used for structural components.

- Strong: the software will calculate and print your model to withstnd a moderate amount of stress (arbitrary). The print will have enough infill to fulfill this "strong" requirement

- Solid: Printer will print your model with 100% infill. Will take the longest amount of time.

- Heal (This corrects any missing of difficient triangles in the model so the software can calculate the actual shape of the model)'

- Center

- Build (This will create the the .cube file in the same directory as the .stl file)

- Attach the USB Key and save to the root folder of the thumbdrive

At this point a .cube file has been generated and you're ready to move on to the next step.

Powering on the Cube

- Make sure the Cube is located on a level surface and the filament feed tube isn't being bent (By a shelf etc..)

- Make sure the power brick is plugged in all the way

- Press the button just below the screen (Screen should wake up)

- You're almost ready to print

Before You Start The Print!!

Make sure you have the following items:

- Elmer's Washable School Glue Stick (Purple Glue Stick)

- Tweezers (Need this to remove the extruder drippings just before the print starts)

Prep the Print Bed (IMPORTANT)

- Remove the glass build plate from the cube (Held on with a magnet so it should just pop off)

- Undo the binder clips to remove the mirrored piece of glass (Remember where the binder clips are positioned)

- Wash/dry the mirrored glass in the sink (Be careful as it's fragile and the edges are sharp)

- if you break the glass don't fret we have replacements. Just make sure to let someone know and record it in the operators log so we know to replace it :-).

- Do a final clean of the mirrored glass using glass cleaner and a paper towel

- Use the glue stick to apply a thin layer of glue to the entire surface of the mirrored glass THOROUGHLY (This is so the plastic will stick but will still be removable when done)

- Reattach the mirrored glass to the build plate with the binder clips

- Make sure that the clips wont obstruct the movement of the build plate

- Best place for the clips are on the right side (Front and Back)

Start the Print

- Eject the USB Key marked "Cube Firmware" from the Laptop and attach to the cube on the right hand side

- Navigate though the LCD menu and find the file you uploaded

- Select it and your print should start

- If you see a message about there not being enough filament just ignore it and continue the print (We reload the cartridges so the cartridge capacity indicator is off)

- After about 10? seconds the print head will move to about 1/2" above the build plate

- It will now begin heating up the extruder.

- Use with the tweezers to remove any filament that comes out as it heats up the extruder for about 30? seconds.

- When the head starts moving again remove your hands and tweezers as it's about to start printing

- Now watch the magic begin :-)

Monitoring the Print

Now that the cube has started printing it's important to keep an eye on it. If at any time you see an issue please cancel the print by hitting the "Stop" button on the display. Here are some things that are cancel worthy:

- You hear a ticking sound coming from the extruder (Extruder is jammed SEE BELOW)

- The extruder is hitting the binder clips (Clips weren't positioned correctly)

- The extruder is bumping over some plastic that hardened in the wrong place

- The print has obviously failed (Help us save plastic and prevent a mess)

- Anything else that may damage the printer or waste plastic

- When the print finishes please turn off the printer (Hold down the button until the cube powers off)

Removing the Print from the Build Plate

You're almost done now it's time for the last step. Removing the print from the build plate.

- Above all be careful when doing the steps below.

- You'll be applying pressure to thin sharp pieces of glass.

- You may want to wear safetly gloves which are located in the safety equipment bin

- Remove the build plate and wash off the glue with warm water from the sink (Takes a while but it does get warm)

- Try to loosen the part from the glass by twising and flexing (Without breaking the part)

- Use a utility knife to GENTLY get under the part and pop it off.

Please Clean up for Others

Please do the following procedure so the next person can use the machine

- Wash/dry the build plate/mirrored glass in the sink and put back on the machine

- Put all the tools back in their storage box

- Make sure you shut off the printer by holding down the button for several seconds (Very Important)

- If you we're happy with your experience please consider putting a buck or 2 in the tip jar :-)

Operators Log

Please provide feedback on our print in the operators log for this printer Cube_Operators_Log

Bed Leveling

I level the bed once a week so you really shouldn't need to do this procedure

- The bed can be leveled through the software.

- There is no need to mechanically level the bed.

- Use a index/business card when going through the leveling procedure.

- You should feel a slight bit of resistance when moving the card in-between the bed and extruder.

Z Axis Height Adjustment

This should allow a index/business card to slide freely underneath it without feeling like it's dragging.

Notes

Wifi Doesn't Work

We had to restore an old firmware to enable us to use our own filament and as a result the Wifi access doesn't work. Your better off just transferring the .cube file to the usb key and printing via the LCD menu.

Hacks that Make This Thing Work

Firmware is hacked to ignore filament cartridge life (aka you can refill cartridges)

Firmware Updates

Please don't because we'll lose the hack that lets us refill the filament.

Pages in category "Cube"

The following 2 pages are in this category, out of 2 total.