Makerbot Operators Log

From HacDC Wiki

When you use the Cupcake, please add notes here. Newest at top.

- Dec 30th, 2010 (Will.) Printed out a test cube with the new machines.xml file. Printed some tiny, flat whistles. Found out that whistles are hard to print.

- Dec 27, 2010. (John, Elliot) swapped out the makerbot standard 1/2 microstepping stepper controllers for a 4-axis board using pololu controllers in 1/16 configuration. The bot is much quieter with the 1/16 microstepping. You will have to update your machines.xml (Makerbot machines.xml) to use the new 1/16 configuration.

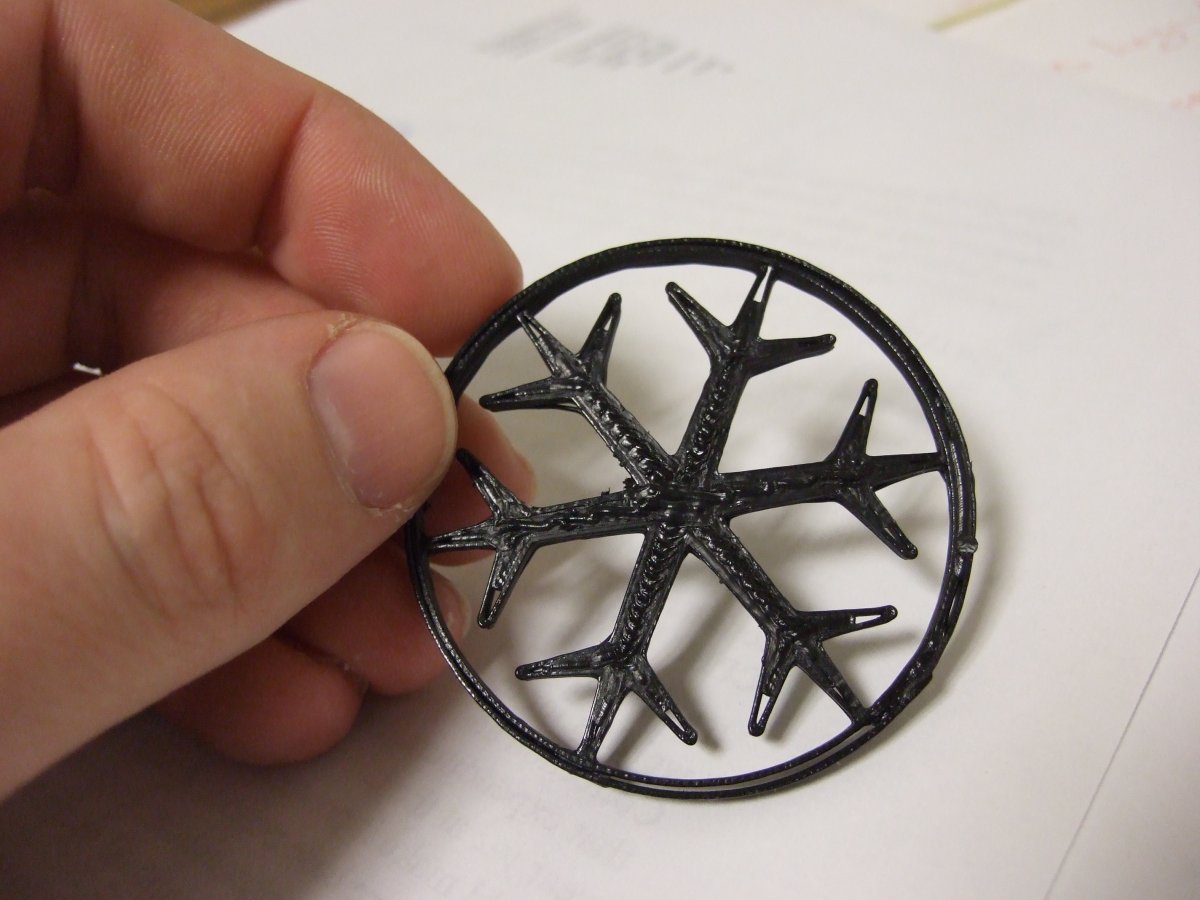

- Dec 20, 2010. (Will.) Printer a bunch of snowflakes for the holiday party. Experimented with raftless printing. Taught Eric how to use the makerbot.

- Dec 20, 2010. (Eric.) Found Will and makerbot in working condition. Printed pretty birthday snowflakes.

- Dec 19, 2010. (Will.) Found makerbot in working condition. Fired up makerbot and extruded some goo for a few minutes, had no problems. Printed a large object, makerbot ran without encountering any problems.

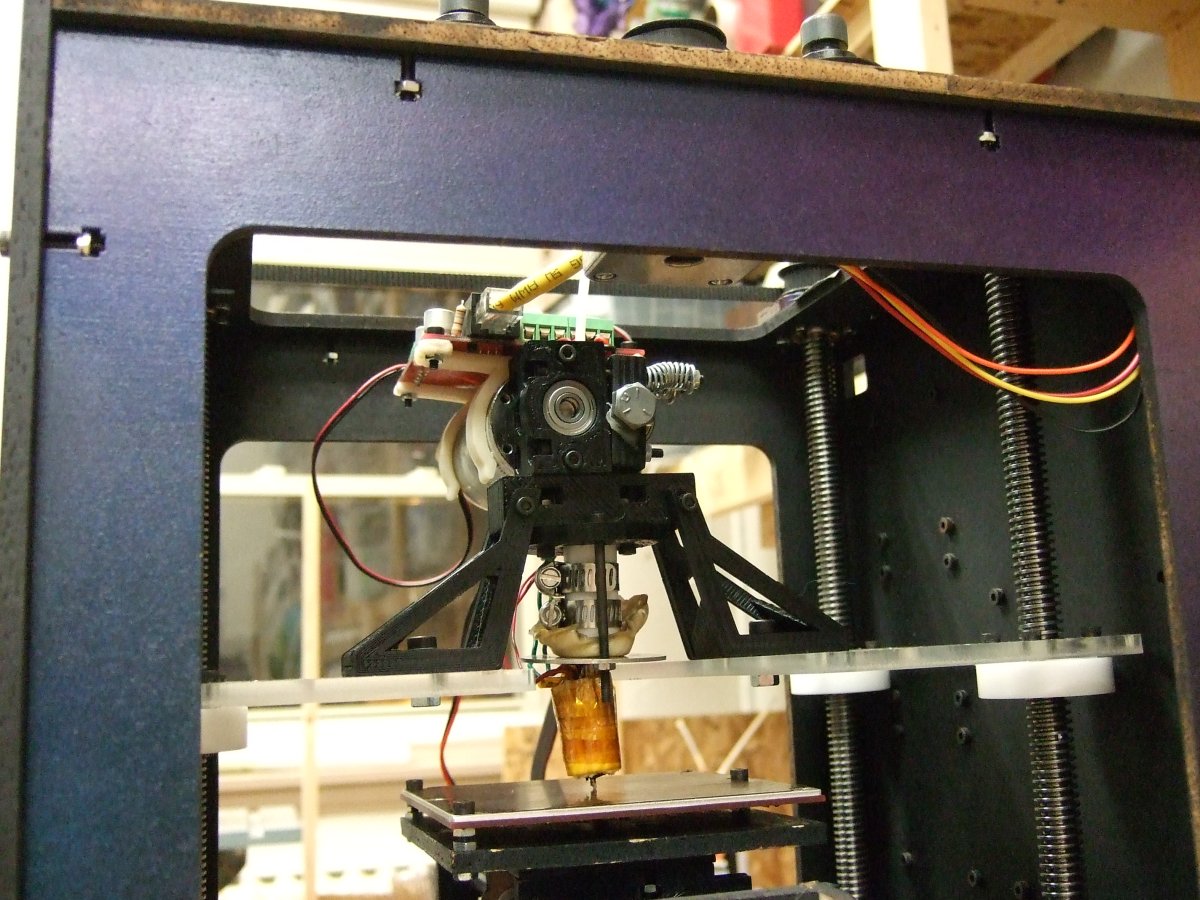

- Dec 17, 2010. (Elliot, Will, Speek.) Replaced the stock v4 extruder head with a self-printed Brutstruder:

Elliot printed some multicolour items for his nieces for Xmas, changing the filament a bunch of times with no problems. Has the brutstruder fixed our filament feed woes?!?!? Stay tuned....

Elliot printed some multicolour items for his nieces for Xmas, changing the filament a bunch of times with no problems. Has the brutstruder fixed our filament feed woes?!?!? Stay tuned....

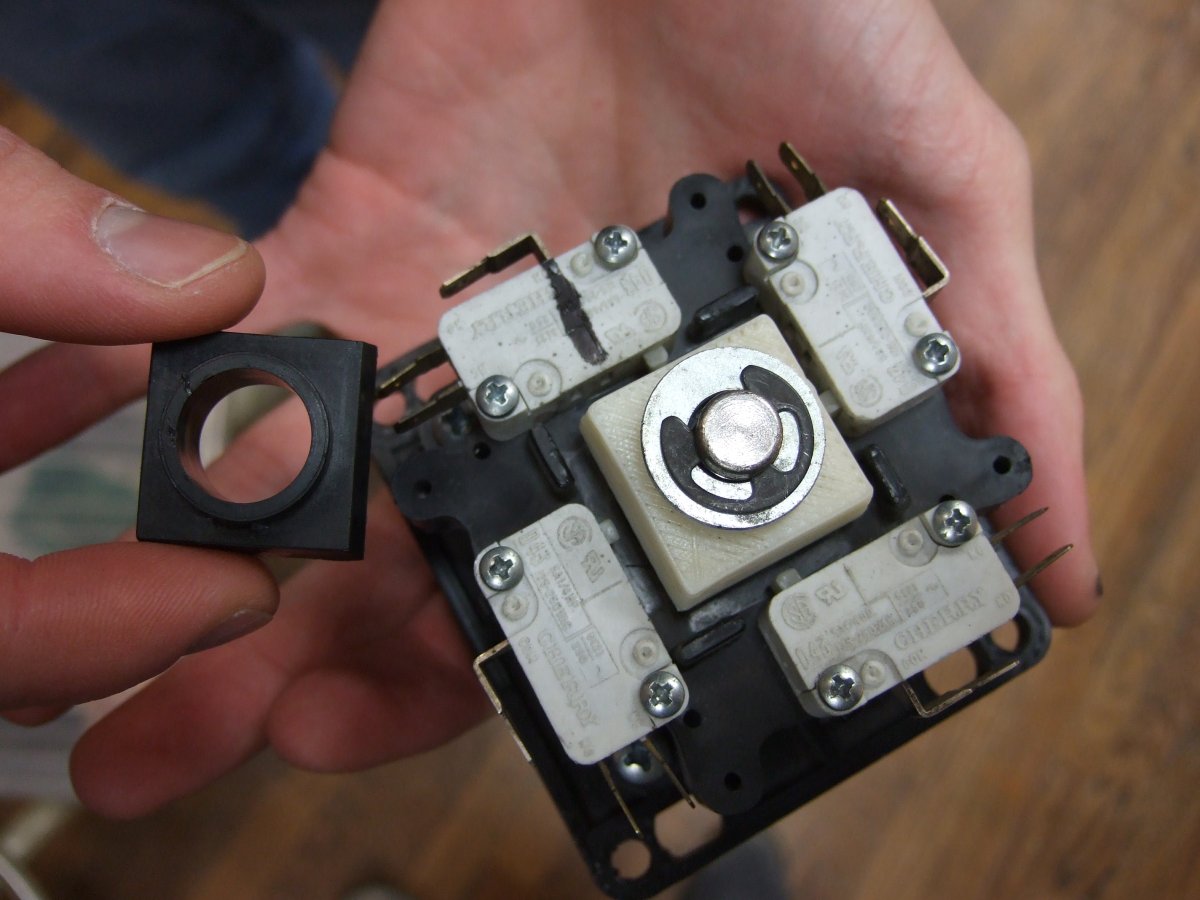

- Dec 10-Dec 15, 2010. (Elliot, Xaq) Much frustration. On-and-off printing, seemingly due to the extruder head not carrying enough force. Got it working with the (wider, more round) white filament, but still having troubles with the (smaller, slightly-oval) black filament. One night when it was working, probably the 13th, Xaq and Nick made up a model for a replacement joystick part.

- Dec 8, 2010. (Xaq and Elliot.) We spent a few hours trying to figure out why the feed wasn't feeding. It would go for a few minutes then stall -- white filament or black filament. Xaq was thinking it was a rotation thing, and we noticed that the drive wheel wants to twist the feedstock around in a circle, putting a twist in it. Elliot noticed a ton of back-pressure from the hot end, and wonders if that's not to blame.

- Dec 3, 2010. (Elliot.) Printed out a bottle opener and it worked just perfectly. Noticed that the feed had a kink in it, and clipped and re-fed it. It didn't print sucessfully since. Tried to print the whistle a few times with no joy. It would stop feeing a few layers into the print. There's something to do with a twist in the feed? Or it the feed slightly oval-shaped and slipping? Fed the makerbot the white ABS feed, which is slightly thicker, and it printed flawlessly. Hmmm...

- Nov 29, 2010. (Elliot and Xaq.) While Xaq was in the space, we both spent about 2 hours of frustratingly abortive 2-minute prints, attempts at raftlessly printing a coathook. Shortly after Xaq left, Elliot printed a coathook with a raft and it worked well enough (with babying on the feed at points). Elliot then printed dino-2s for the brutstruder without rafts with only one flaw in the first of five prints. I'm at a loss for what changed: it got later at night, and the machine had been in continuous use for longer. I wonder if the bot needs much longer to warm up than we thought? Anyway, before printing something raftless, I would try printing a rafted small object first as a sacrifice to the makerbot gods (or at least to verify that the machine is working) because that seems to be a lot less tweaky.

- Nov 27, 2010. (Elliot.) Printed small odds and ends, just to watch it go. Looks great. The new spool which Dan B and I built seems to work fine, and certainly won't tangle. Moved it to its own (partly mobile) table. I've been working on raftless settings, and it's looking great. Printed a few of the heater-retainer collars for later in case we need them, and tossed them in the reprap box. It's about 5 hours of printing time since the rebuild and it's behaving flawlessly. Will this continue? Knock on wood.

- Nov 26, 2010. (Elliot.) Having broken the hot end of the extruder, I needed to fix it. Took it completely apart and soaked all the parts in acetone, getting all the melted plastic off. I reinstalled things as per the makerbot instructions, with the exception of using teflon tape to (electrically) insulate the barrel from the nichrome wire, because its original sheathing had come off during removal. Noticed that the brass barrel was installed upside-down, so I fixed that. The nozzle seems to be flowing a lot now -- so much that I had to reconfigure skeinforge to deal with the extra plastic. We'll see if it holds up. Printed out a brutstruder and the plastic axles for the new feed spool.

- Nov 24, 2010. (Elliot and Will G.) Still having problems with intermittent extruder stoppage. Will and Elliot removed the hot end and cleaned it out. That wasn't the problem. Elliot noticed that the idler wheel was binding, fixed that. Still not the problem, though it has sufficient strength to push through whatever is giving the high back-pressure. Elliot started to re-do the hot end again, and probably messed up the heater in the process. Hopefully it's just a loose wire, but the insulation and heating element may need to be re-worked. Sucks....

- Nov 20, 2010. (Elliot and Tommy) Noticed that gear motor was out of line. Tommy and I added a bearing to it. Extruder still just randomly stops extruding after 15 minutes or so.

- Nov 18, 2010. (Elliot) Printed out some widgets. Extruder head stopped extruding halfway through a print, turned out to be due to ABS bits fouling up the pushing-gear teeth. Also had some troubles with adhesion of the raft to platform.