PrusaMendel: Difference between revisions

From HacDC Wiki

No edit summary |

No edit summary |

||

| Line 1: | Line 1: | ||

[[Category:3D_Printing]] | [[Category:3D_Printing]] | ||

[[Category:Equipment]] | [[Category:Equipment]] | ||

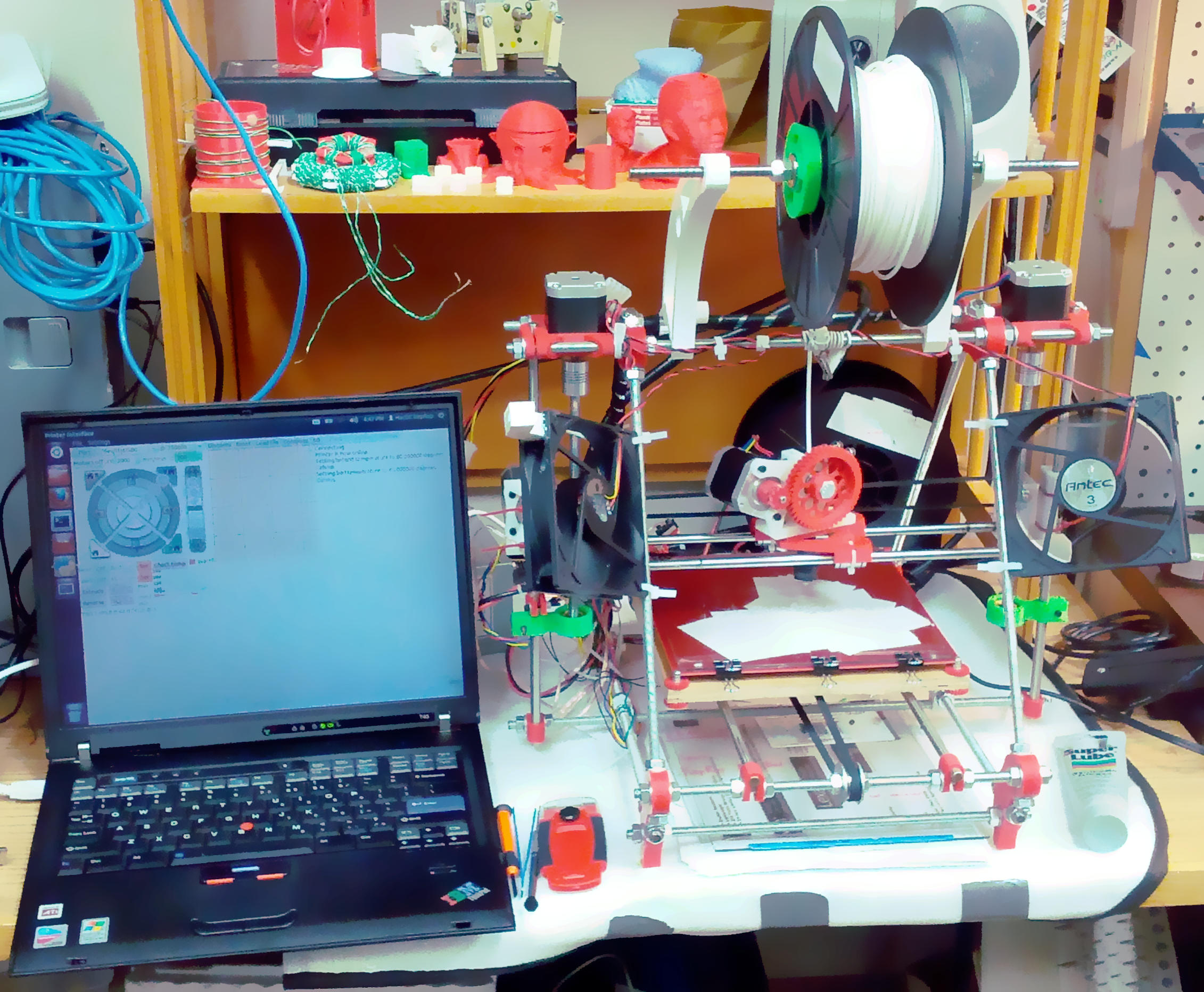

HacDC's Prusa Mendel 3D Printer. [[File:HacDCprusaMendel2013-02-11.jpg|500px|right]] | |||

=Current Machine Status= | |||

'''"git pull" needed on laptop''' | |||

=Operation= | |||

==Firing Up== | |||

#Emergency Stop. Be ready to unplug USB cable when beginning X/Y/Z motion. | |||

#Go through the routine maintenance list as necessary, especially the safety section. | |||

#Check which bed you are using. Bare glass recommended for quality. Adding blue paper tape can improve poor alignment and dirt tolerance. | |||

#Turn on power strip. Switch on the ATX PSU behind the machine. | |||

#Open pronterface. Connect to the printer. Check box "Watch" to see temperature readings. You should see about 20C on all temperature sensors, and basic stats in the console window. Optionally, set heated bed to 55C for bare glass. If you don't do this now, the printer will wait for the bed to heat up later. | |||

==File Preparation== | |||

#Load an STL model onto the dedicated laptop for printing. If you haven't made one, download one from [http://www.thingiverse.com/ Thingiverse]. | |||

#Clean the STL model. Load file in nefabb, click the red "+", "Automatic repair", "Default repair", "Apply repair", "Yes" - remove old part. Finally, export part as STL, repairing more errors if prompted. | |||

#Open Slic3r. Drag your STL file from a file manager onto the "Drag your objects here" box in Slic3r. | |||

#"Print settings: Cheap" "Filament: HacDC" "Printer: HacDC" . | |||

#Export G-Code in Slic3r. | |||

#Wait for Slic3r to finish. In pronterface, load the G-Code file you have created. A preview of the first layer should appear in the middle of Pronterface. You can click on the preview and walk through the layers by holding shift and scrolling on the trackpad. In the console (not the bottom bar), an accurate time estimate for the print should also appear. | |||

==Printing== | |||

#Once again, make sure you can push X and Y axes to their endstop switches without bumping anything. Also make sure there is not more than 1mm of ooze sticking out of the nozzle to avoid crashing the extruder into the bed. | |||

#Click the "print" button. | |||

#Wait for bed to cool. Apply gentle hammer taps with sharp pointy tool to the base of your object. After a few gentle taps in various places, it will usually pop off the bed cleanly. | |||

=Routine Maintenance - ALWAYS CHECK= | |||

==FIRE HAZARDS== | |||

*Power Supply. NEVER leave ATX power supply on after leaving HacDC, it gets hot. | |||

*Temperature Sensor. NEVER heat the bed without temperature sensor in place. | |||

==Machine Damage== | |||

*X/Y endstops. Manually push X/Y axes to test the switches. Make sure the extruder and bed are positioned not to bump anything when homing. | |||

*Z-axis endstop. Visually check that it will trigger before severe crash into print bed. Also trim excess cold plastic ooze on the nozzle if necessary. | |||

*Lose bolts. In particular, check the endstop bolts. | |||

*Loose wires. Short circuits cause severe damage. | |||

==Bed Cleaning== | |||

*Bare glass bed must be extremely clean. If bed is level to within 0.25mm, and plastic is not sticking, it needs cleaning. Take glass to sink, apply dishwashing soap, sponge, and elbow grease. | |||

*Blue paper tape may be used on glass or polycarbonate bed. Surface adhesion is more predictable. Downside is the need to occasionally replace the paper tape. | |||

*Polycarbonate bed should be kept flat, without excessive protrusions. Scrape excess plastic off, and trim deep cuts. | |||

==Z-Axis== | |||

*First-layer depth. Bare glass bed requires exactly 0.2mm between nozzle and bed. Polycarbonate and paper tape beds tolerate direct contact, allowing nozzle to be driven 0.4mm into the bed. In pronterface, home the Z-axis, then manually jog 0.1mm to verify these distances. | |||

*Z-axis height. Z-axis endstop position sets depth for entire bed. | |||

*Z-axis level. The dual threaded rods must be kept aligned. | |||

*Bed leveling. Place Z-axis just above bed, then jog X/Y axes. Place thin paper strips under bed until level. | |||

=Please Avoid= | |||

You are adding to the workload on a shared machine. Please be gentle. | |||

*NEVER leave ATX power supply on after leaving HacDC, it gets hot. | |||

*NEVER heat the bed without temperature sensor in place. | |||

*Printing faster than 65mm/s without acceleration incurs excessive stress and more frequent maintenance. | |||

*Manually moving Z-axis threaded rods delevels machine, which takes time to fix. | |||

*Heating raw polycarbonate bed above 45C will give extreme adhesion. Even if you can remove your part, you will likely warp the bed doing so. | |||

Revision as of 19:36, 26 April 2013

HacDC's Prusa Mendel 3D Printer.

Current Machine Status

"git pull" needed on laptop

Operation

Firing Up

- Emergency Stop. Be ready to unplug USB cable when beginning X/Y/Z motion.

- Go through the routine maintenance list as necessary, especially the safety section.

- Check which bed you are using. Bare glass recommended for quality. Adding blue paper tape can improve poor alignment and dirt tolerance.

- Turn on power strip. Switch on the ATX PSU behind the machine.

- Open pronterface. Connect to the printer. Check box "Watch" to see temperature readings. You should see about 20C on all temperature sensors, and basic stats in the console window. Optionally, set heated bed to 55C for bare glass. If you don't do this now, the printer will wait for the bed to heat up later.

File Preparation

- Load an STL model onto the dedicated laptop for printing. If you haven't made one, download one from Thingiverse.

- Clean the STL model. Load file in nefabb, click the red "+", "Automatic repair", "Default repair", "Apply repair", "Yes" - remove old part. Finally, export part as STL, repairing more errors if prompted.

- Open Slic3r. Drag your STL file from a file manager onto the "Drag your objects here" box in Slic3r.

- "Print settings: Cheap" "Filament: HacDC" "Printer: HacDC" .

- Export G-Code in Slic3r.

- Wait for Slic3r to finish. In pronterface, load the G-Code file you have created. A preview of the first layer should appear in the middle of Pronterface. You can click on the preview and walk through the layers by holding shift and scrolling on the trackpad. In the console (not the bottom bar), an accurate time estimate for the print should also appear.

Printing

- Once again, make sure you can push X and Y axes to their endstop switches without bumping anything. Also make sure there is not more than 1mm of ooze sticking out of the nozzle to avoid crashing the extruder into the bed.

- Click the "print" button.

- Wait for bed to cool. Apply gentle hammer taps with sharp pointy tool to the base of your object. After a few gentle taps in various places, it will usually pop off the bed cleanly.

Routine Maintenance - ALWAYS CHECK

FIRE HAZARDS

- Power Supply. NEVER leave ATX power supply on after leaving HacDC, it gets hot.

- Temperature Sensor. NEVER heat the bed without temperature sensor in place.

Machine Damage

- X/Y endstops. Manually push X/Y axes to test the switches. Make sure the extruder and bed are positioned not to bump anything when homing.

- Z-axis endstop. Visually check that it will trigger before severe crash into print bed. Also trim excess cold plastic ooze on the nozzle if necessary.

- Lose bolts. In particular, check the endstop bolts.

- Loose wires. Short circuits cause severe damage.

Bed Cleaning

- Bare glass bed must be extremely clean. If bed is level to within 0.25mm, and plastic is not sticking, it needs cleaning. Take glass to sink, apply dishwashing soap, sponge, and elbow grease.

- Blue paper tape may be used on glass or polycarbonate bed. Surface adhesion is more predictable. Downside is the need to occasionally replace the paper tape.

- Polycarbonate bed should be kept flat, without excessive protrusions. Scrape excess plastic off, and trim deep cuts.

Z-Axis

- First-layer depth. Bare glass bed requires exactly 0.2mm between nozzle and bed. Polycarbonate and paper tape beds tolerate direct contact, allowing nozzle to be driven 0.4mm into the bed. In pronterface, home the Z-axis, then manually jog 0.1mm to verify these distances.

- Z-axis height. Z-axis endstop position sets depth for entire bed.

- Z-axis level. The dual threaded rods must be kept aligned.

- Bed leveling. Place Z-axis just above bed, then jog X/Y axes. Place thin paper strips under bed until level.

Please Avoid

You are adding to the workload on a shared machine. Please be gentle.

- NEVER leave ATX power supply on after leaving HacDC, it gets hot.

- NEVER heat the bed without temperature sensor in place.

- Printing faster than 65mm/s without acceleration incurs excessive stress and more frequent maintenance.

- Manually moving Z-axis threaded rods delevels machine, which takes time to fix.

- Heating raw polycarbonate bed above 45C will give extreme adhesion. Even if you can remove your part, you will likely warp the bed doing so.

Pages in category "PrusaMendel"

The following 5 pages are in this category, out of 5 total.