Makerbot Operators Log: Difference between revisions

From HacDC Wiki

Hexagon5un (talk | contribs) |

Hexagon5un (talk | contribs) |

||

| Line 1: | Line 1: | ||

==== When you use the Cupcake, please add notes here. Newest at top. ==== | ==== When you use the Cupcake, please add notes here. Newest at top. ==== | ||

* June 12, 2011 (Elliot) So the experimental hot end idea I was playing around with is a failure. Basically, it doesn't seem to transfer heat into the barrel fast enough with the result that it was very very hard to push filament through. I found some nichrome wire (7 ohms worth) and re-wrapped the barrel in the old style. | |||

* June 11, 2011 (Elliot) R. Mark Adams dropped a high-temp thermistor by the space, so I'm working on the hot end again. I set up the extruder thermistor for 10K resistance, and the rest looked good (beta = 4450, base = 25). Tested with a cup of hot water at 83 C and it read spot on. I declare it calibrated. (Also changed platform thermistor to 10K.) On first warm-up, it looks like the new heater will work, but the PID coefficients are horribly wrong and it's overshooting the set temperature by quite a lot. Tweaked a little bit, ended up with P=8, I=0.1, D=12. Not perfect, but not patient enough to tune further ATM. | * June 11, 2011 (Elliot) R. Mark Adams dropped a high-temp thermistor by the space, so I'm working on the hot end again. I set up the extruder thermistor for 10K resistance, and the rest looked good (beta = 4450, base = 25). Tested with a cup of hot water at 83 C and it read spot on. I declare it calibrated. (Also changed platform thermistor to 10K.) On first warm-up, it looks like the new heater will work, but the PID coefficients are horribly wrong and it's overshooting the set temperature by quite a lot. Tweaked a little bit, ended up with P=8, I=0.1, D=12. Not perfect, but not patient enough to tune further ATM. | ||

Revision as of 19:50, 12 June 2011

When you use the Cupcake, please add notes here. Newest at top.

- June 12, 2011 (Elliot) So the experimental hot end idea I was playing around with is a failure. Basically, it doesn't seem to transfer heat into the barrel fast enough with the result that it was very very hard to push filament through. I found some nichrome wire (7 ohms worth) and re-wrapped the barrel in the old style.

- June 11, 2011 (Elliot) R. Mark Adams dropped a high-temp thermistor by the space, so I'm working on the hot end again. I set up the extruder thermistor for 10K resistance, and the rest looked good (beta = 4450, base = 25). Tested with a cup of hot water at 83 C and it read spot on. I declare it calibrated. (Also changed platform thermistor to 10K.) On first warm-up, it looks like the new heater will work, but the PID coefficients are horribly wrong and it's overshooting the set temperature by quite a lot. Tweaked a little bit, ended up with P=8, I=0.1, D=12. Not perfect, but not patient enough to tune further ATM.

- May 30, 2011 (Elliot) OK, so I re-flashed the firmware on both the extruder (firmware 2.4) and the motherboard (firmware 2.3). If someone wants to order a new thermistor for the hot end, that'd be swell. In the process of updating the firmware, we lost the thermistor calibration for the HBP, so it'll need re-calibrating (it's 110 C is only warm to the touch). Not sure that the all-aluminum hot end heater is getting hot enough -- there was much resistance when I tried to run filament through it. It'll probably need re-jiggering.

- May 29, 2011 (Elliot) Busted even worse now, and I'm in Germany until June 8th. Sorry y'all. The symptoms: The heater core works, but is slow. The replacement thermistors I ordered were low-temp and burned out, so there's no temp feedback. (I've stuck one into the thermistor input directly, you can verify that it reads temperature nearly-correctly. It will fail at 150 degrees, though.) The motor control seems to be not responding, as do the heated platform and nozzle heaters. Is there something wrong in the 12v power section of the board? Are _all_ the FETs burned out? I've double-checked the wiring, but if someone else would go over it, that'd be swell. Extruder motor works when plugged into external 12v. Extruder hot-end is only on finger-tight. If you get it working enough, tighten it back down before use.

- May 23, 2011 (Elliot) Well, the bot is slightly hosed now. I was printing out a bit for a visitor as a demo (figures!) and the heater gave up the ghost -- some of the nichrome wire fatigued and broke. I decided the necessary hot-end rebuild would be a good opportunity to machine out an aluminum cylinder, cut out alu shims to wedge three suitable power resistors inside, and use that as a barrel heater. It works, but takes ten minutes or so to heat up. And then the thermistor we've been using died (open-circuit) leaving the temp sensor always reading 255 degrees C. So now we've got an experimental (slightly slow) heater design with no temperature feedback. Sub-optimal. This will not stand! Stay tuned.

- May 16, 2011 (Elliot) OK, so nobody has been writing stuff down in the log. Booo!! I re-levelled the bed last night. Should be good for printing raftless now. I'm working on a no-tweak-necessary profile for a recent skeinforge that'll allow raftless printing. I think we'll need a z-minimum endstop to make that work.

- Mid April, 2011 (Elliot) Printed out wheels, gears, a carriage, and a bowing arm for Alberto and my art project "Carrier". On display at the Artisphere until June 18th. I'll have to do a thorough writeup.

- March 20, 2011 (Will G) Printed a bottle opener. Had to back the blue filament out and refeed it, since it stopped feeding after 20 seconds. After clipping and refeeding the filament, the makerbot happily printed my bottle opener.

- Feb 20, 2011 (Elliot) Saw that the bearing that holds the motor gear in place was slipping out (for the last time!). Measured the diameter of the hole, SCADed up a part, printed it up, and acetoned it in place. Now the bearing is (forever?) captive.

- Feb 3, 2011 (Elliot) Came in to find a relay attached to the extruder head motor. Removed it (because I do PWM) and discovered why it was there -- the motor was stopping intermittently. After replacing the power cable and a few other things, I finally scavenged the (new) motor off of the RepRap, and that did the trick. Printed a few piezo-disc holders for an art piece.

- Jan 30, 2011 (Elliot) Found out what was wrong with the extruder head (just after Xaq left, as usual) which was that the bearing that holds the motor spindle in place had worked out, so that the motor was no longer held tight against the sprung pulley wheel bearing. Unscrewed the motor from the mount, pushed the bearing back in, and it's working again. Next time the extruder head is off, we should probably epoxy the bearing in or something. Printed out a new Z-crank and then got to work on Xaq's Mendel X-end-motor piece. This was quite hard to get it working with raftless. The tricks: slow the first layer speed down to 0.7 on the infill, 0.45 on the perimeter, and 0.9 for the flow-rate multiplier to keep it from getting too gunky. I also started the prints off with the head a lot closer to the platform than normal. This seemed to squish it down hard, while not putting down so much plastic that it got the hairy over-extrusion condition, which then catches the head on the next pass. It's hard to quantify all this -- we should get a z-axis end-stop installed to establish a reference point.

- Jan 27th, 2011 (Xaq) After a couple weeks of basically flawless printing, the extruder motor seems to be giving up. I saw this today and on Tuesday when Pete was printing a Wade's: after a little over an hour, the extruder motor just stops. After the failure, attempting to control extrusion through the control panel also fails. Pete fixed it on Tuesday by toggling to motor back and forth (I think), but I am not sure how he did that so I am giving up for today. These motors are notorious in the reprap-blogosphere for suckiness, it may be time for a geared stepper....

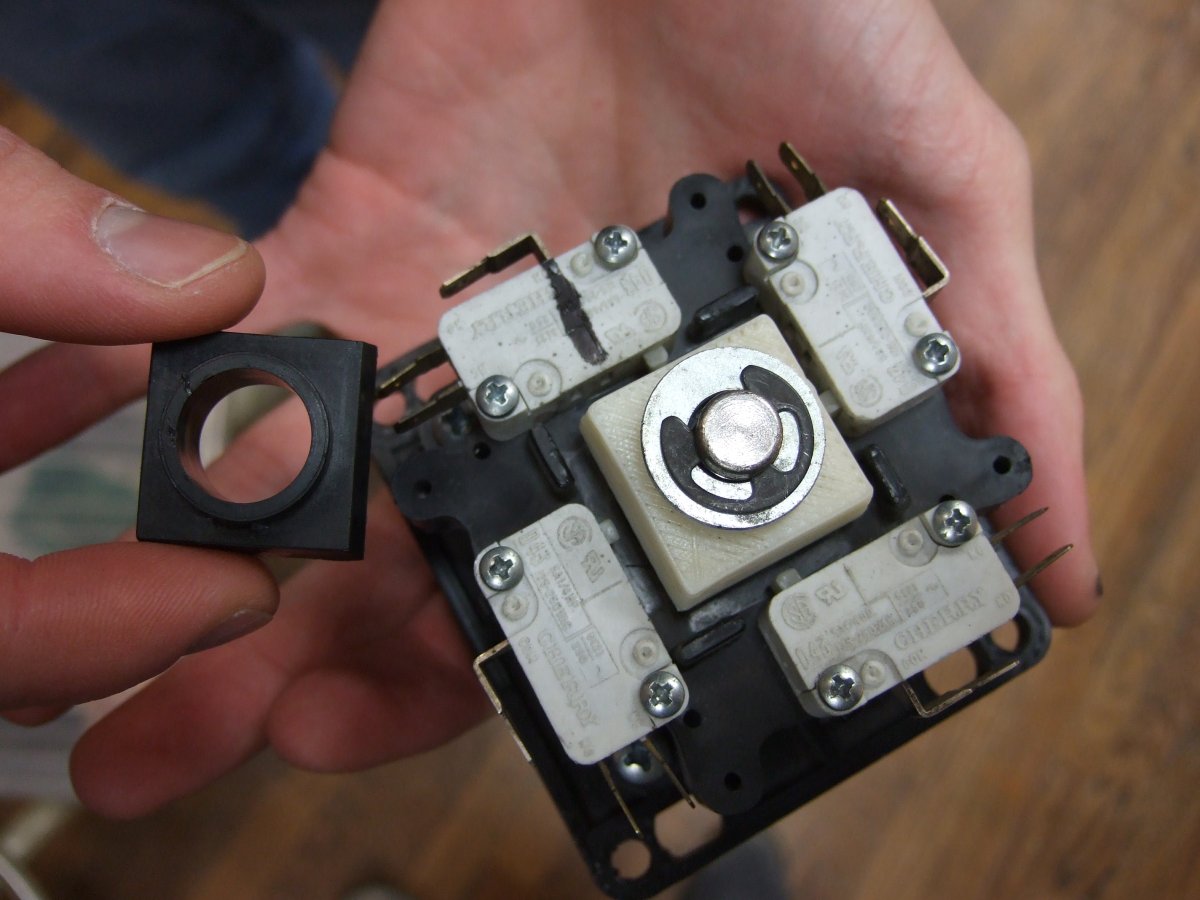

- Jan 11th, 2011 (Xaq, Peter (?), Elliot) Peter (?) was printing out Mendel parts in three (?) five-hour batches and during a four-hour print, the machine failed. It looks like the barrel clogged up somehow and the resistance messed up the feed section. Specifically, the retaining ring was all bent and the motor shaft had come out of its bearing. Xaq broke the hot-end down and cleaned it all out, and we re-assembled the head. We already had a retaining ring printed out from before (it's a common superstition to have an extra on hand, and now I see why) so it was just a question of assembly. We noticed that the printed retaining ring design isn't quite centered on the dimple in the brutstruder. A little work with a file makes it fit right. We then printed out another replacement retaining ring for next time and tossed it in the reprap box.

- Jan 3, 2011 (Elliot, John) Printed out a bunch of cool, small objects for people to see. Then printed out a bolt-hobbing tool attachment for the lathe b/c John wanted a hobbed bolt for his Mendel. Then we hobbed it on the lathe and it was rad. The hobbing tool now sits in the reprap box, waiting expectantly for you to use it.

- Dec 30th, 2010 (Will.) Printed out a test cube with the new machines.xml file. Printed some tiny, flat whistles. Found out that whistles are hard to print.

- Dec 27, 2010. (John, Elliot) swapped out the makerbot standard 1/2 microstepping stepper controllers for a 4-axis board using pololu controllers in 1/16 configuration. The bot is much quieter with the 1/16 microstepping. You will have to update your machines.xml (Makerbot machines.xml) to use the new 1/16 configuration.

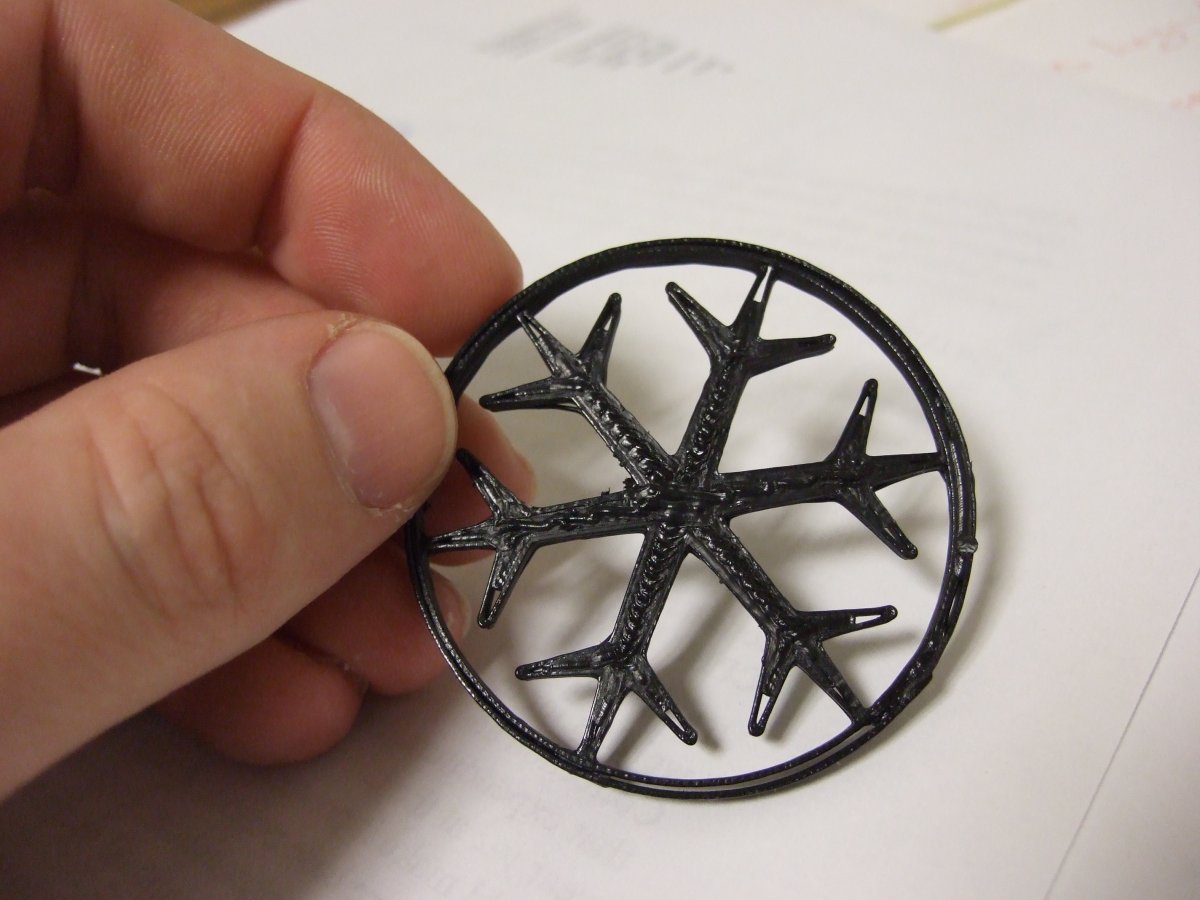

- Dec 20, 2010. (Will.) Printer a bunch of snowflakes for the holiday party. Experimented with raftless printing. Taught Eric how to use the makerbot.

- Dec 20, 2010. (Eric.) Found Will and makerbot in working condition. Printed pretty birthday snowflakes.

- Dec 19, 2010. (Will.) Found makerbot in working condition. Fired up makerbot and extruded some goo for a few minutes, had no problems. Printed a large object, makerbot ran without encountering any problems.

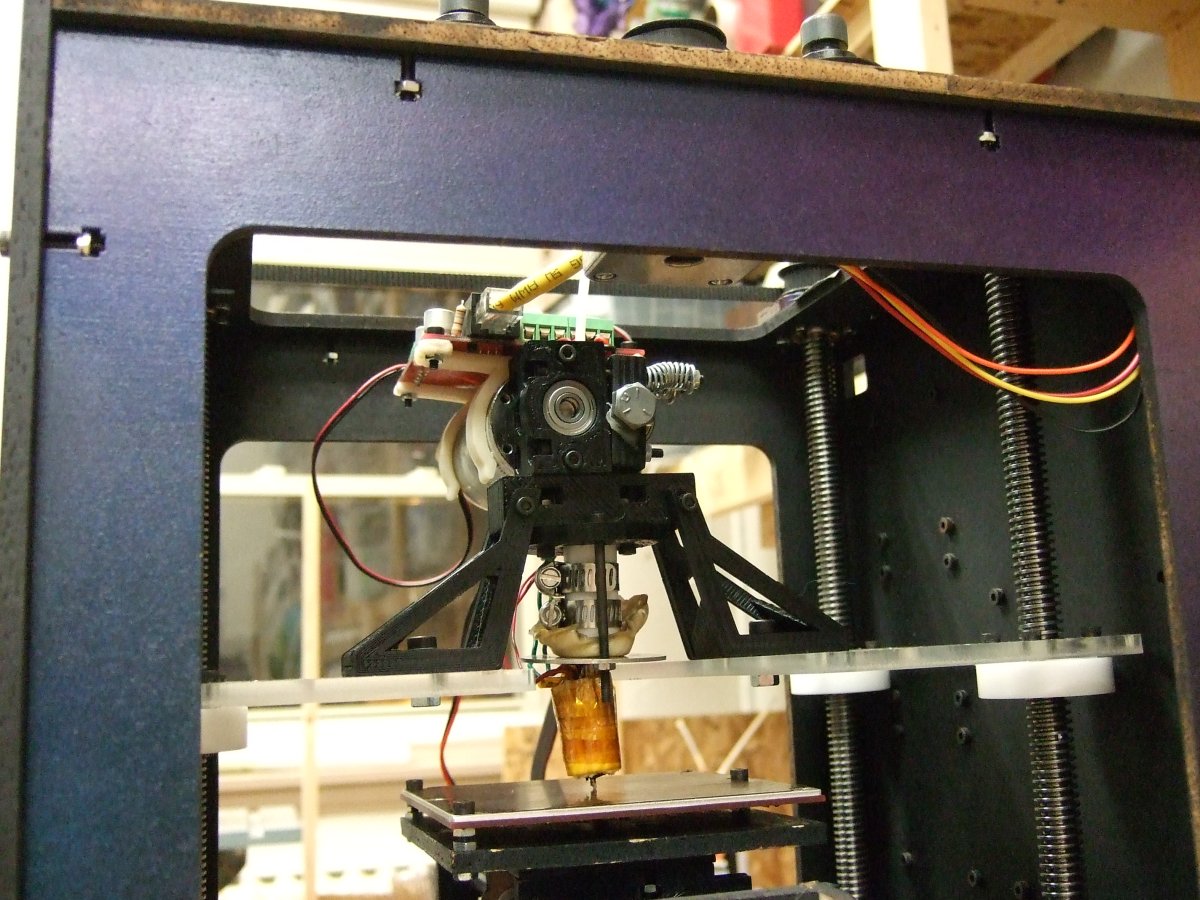

- Dec 17, 2010. (Elliot, Will, Speek.) Replaced the stock v4 extruder head with a self-printed Brutstruder:

Elliot printed some multicolour items for his nieces for Xmas, changing the filament a bunch of times with no problems. Has the brutstruder fixed our filament feed woes?!?!? Stay tuned....

Elliot printed some multicolour items for his nieces for Xmas, changing the filament a bunch of times with no problems. Has the brutstruder fixed our filament feed woes?!?!? Stay tuned....

- Dec 10-Dec 15, 2010. (Elliot, Xaq) Much frustration. On-and-off printing, seemingly due to the extruder head not carrying enough force. Got it working with the (wider, more round) white filament, but still having troubles with the (smaller, slightly-oval) black filament. One night when it was working, probably the 13th, Xaq and Nick made up a model for a replacement joystick part.

- Dec 8, 2010. (Xaq and Elliot.) We spent a few hours trying to figure out why the feed wasn't feeding. It would go for a few minutes then stall -- white filament or black filament. Xaq was thinking it was a rotation thing, and we noticed that the drive wheel wants to twist the feedstock around in a circle, putting a twist in it. Elliot noticed a ton of back-pressure from the hot end, and wonders if that's not to blame.

- Dec 3, 2010. (Elliot.) Printed out a bottle opener and it worked just perfectly. Noticed that the feed had a kink in it, and clipped and re-fed it. It didn't print sucessfully since. Tried to print the whistle a few times with no joy. It would stop feeing a few layers into the print. There's something to do with a twist in the feed? Or it the feed slightly oval-shaped and slipping? Fed the makerbot the white ABS feed, which is slightly thicker, and it printed flawlessly. Hmmm...

- Nov 29, 2010. (Elliot and Xaq.) While Xaq was in the space, we both spent about 2 hours of frustratingly abortive 2-minute prints, attempts at raftlessly printing a coathook. Shortly after Xaq left, Elliot printed a coathook with a raft and it worked well enough (with babying on the feed at points). Elliot then printed dino-2s for the brutstruder without rafts with only one flaw in the first of five prints. I'm at a loss for what changed: it got later at night, and the machine had been in continuous use for longer. I wonder if the bot needs much longer to warm up than we thought? Anyway, before printing something raftless, I would try printing a rafted small object first as a sacrifice to the makerbot gods (or at least to verify that the machine is working) because that seems to be a lot less tweaky.

- Nov 27, 2010. (Elliot.) Printed small odds and ends, just to watch it go. Looks great. The new spool which Dan B and I built seems to work fine, and certainly won't tangle. Moved it to its own (partly mobile) table. I've been working on raftless settings, and it's looking great. Printed a few of the heater-retainer collars for later in case we need them, and tossed them in the reprap box. It's about 5 hours of printing time since the rebuild and it's behaving flawlessly. Will this continue? Knock on wood.

- Nov 26, 2010. (Elliot.) Having broken the hot end of the extruder, I needed to fix it. Took it completely apart and soaked all the parts in acetone, getting all the melted plastic off. I reinstalled things as per the makerbot instructions, with the exception of using teflon tape to (electrically) insulate the barrel from the nichrome wire, because its original sheathing had come off during removal. Noticed that the brass barrel was installed upside-down, so I fixed that. The nozzle seems to be flowing a lot now -- so much that I had to reconfigure skeinforge to deal with the extra plastic. We'll see if it holds up. Printed out a brutstruder and the plastic axles for the new feed spool.

- Nov 24, 2010. (Elliot and Will G.) Still having problems with intermittent extruder stoppage. Will and Elliot removed the hot end and cleaned it out. That wasn't the problem. Elliot noticed that the idler wheel was binding, fixed that. Still not the problem, though it has sufficient strength to push through whatever is giving the high back-pressure. Elliot started to re-do the hot end again, and probably messed up the heater in the process. Hopefully it's just a loose wire, but the insulation and heating element may need to be re-worked. Sucks....

- Nov 20, 2010. (Elliot and Tommy) Noticed that gear motor was out of line. Tommy and I added a bearing to it. Extruder still just randomly stops extruding after 15 minutes or so.

- Nov 18, 2010. (Elliot) Printed out some widgets. Extruder head stopped extruding halfway through a print, turned out to be due to ABS bits fouling up the pushing-gear teeth. Also had some troubles with adhesion of the raft to platform.