OpticalTableRobot: Difference between revisions

From HacDC Wiki

(assembled.) |

|||

| Line 9: | Line 9: | ||

=Status= | =Status= | ||

Assembled and operational. | |||

=Features= | =Features= | ||

Revision as of 23:43, 10 January 2016

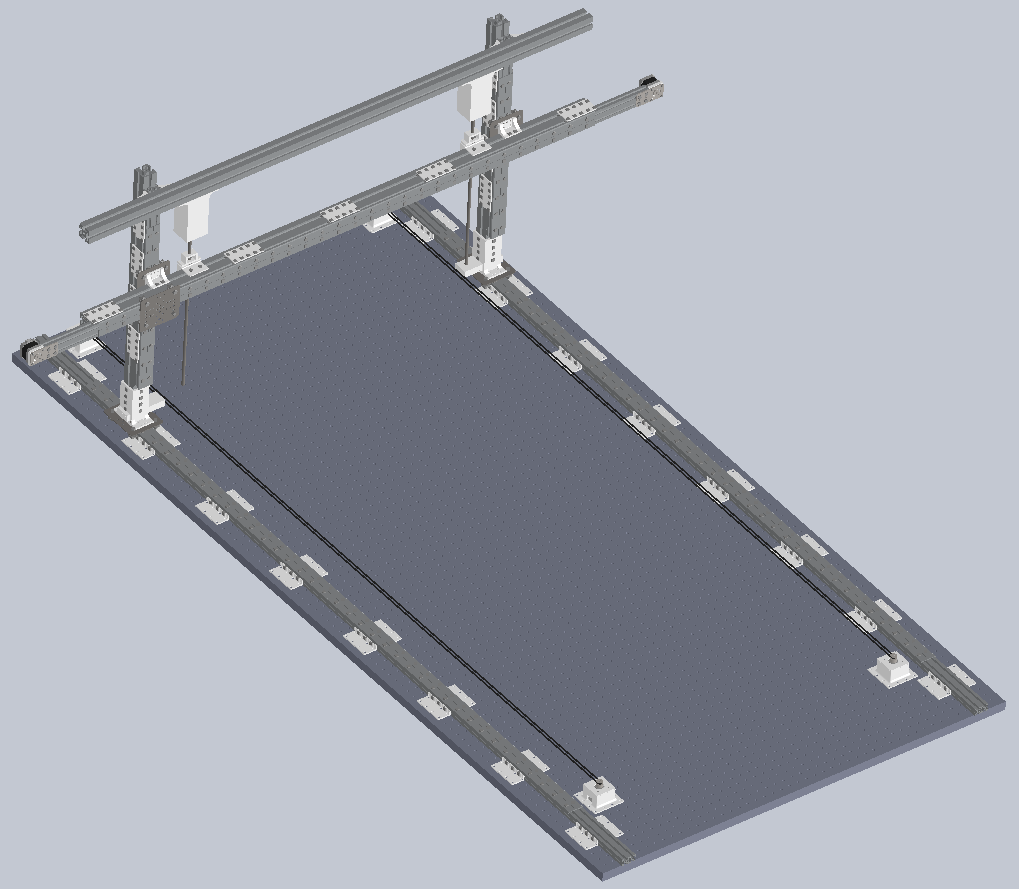

Multi-tool CNC platform in progress atop the optical table to enable ultra-precise fabrication on a massive scale. Derived from, and tool-compatible with, FlexReplicator.

This is the kind of machine one might use to 3D print large herringbone power transmissions for lost PLA casting, or carry out a VLSI production run.

Status

Assembled and operational.

Features

- Approximately 8'x4' build area.

- Precision better than 2um. Thought to be upgradeable to 15nm precision. (Visible light has a wavelength approximately 500nm or 0.5um.)

- Rock-solid, supported by true optical table and 40 series extrusions. Low maintenance and high reliability.

- Supports multiple tools and capabilities, from 3D printing and CNC milling to VLSI photolithography.

- Simultaneous multi-tool use enhances performance, as with milling down 3D printed layers.

Documentation

Design hosted on github.

Tools

Extruders

In progress. Works just like any other 3D printer. Plan on at least two nozzles, one for high-precision (<0.35mm), one for high-speed (>1mm).

Pick And Place

In Progress. camera system, part feeders, and vacuum based pick up and rotate tool will need no be added.

Mill

In progress. Standard 120V AC drill, connected to control circuitry by SSR.

UV Laser

In progress. Planned as >2W and <1um focal spot. Suitable for precision work through opaque materials (paper, wood, foam, spraypaint, some plastics) rather than cookie cutting.

VLSI Projection Lithography

Modified (ultraviolet) DLP projector and camera mounted to microscope, used for high-resolution patterning. Absolute accuracy (inter-frame) is expected to be ~2um, while relative accuracy (intra-frame) is expected to be <0.5um, scalable down to diffraction-limited performance.

Casting

Direct metal printing thus far is either highly expensive, low-strength, or both. Compromise is to 3D print a plastic (PLA) part, then cast it to metal. Besides low cost, this process can be used to achieve parts traditionally infeasible, like pre-assembled herringbone-gear power transmissions.

Pricing

As with other HacDC tools, operators are asked to pay for consumables used only for heavy usage. However, this machine can easily consume an entire a few hundred dollars of filament in one job...

Safety

Usual safety precautions apply. Additionally, open operation of a Class 4 laser demands eye protection for anyone in the room. Catastrophic retina damage will occur instantly upon viewing the projected spot, which is no less hazardous than direct beam viewing. This is especially true for lasers with a <10um wavelength (ie. non-CO2, eg. ultraviolet).

Assembly

First, attach the makerslide to all of the rail segments. Do this by placing the nut in the t slot (flat side up), sliding the makerslide until the screw hole lines up with the nut, then threading the bolt into the nut. Do not tighten, so that the makerslide slides easily when placing the next bolt/nut pair.

Upgrades

Once the basic platform has been deployed, simple upgrades may be applied if necessary. These may be particularly relevant to edge cases like CNC milling or VLSI patterning. However, these upgrades involve tradeoffs (ie. inertia, friction, cost, etc), and should only be applied upon discovery of a clear requirement.

Relative Accuracy (Vibration)

- Multiple Z-Axis gantries.

- Additional Z-axis actuators.

- Z-axis threaded rod stabilizers.

- Interferometric linear optical encoders.

- Magnetic brakes and micro-actuator stages.

Maximum Force

- Vectran rope timing belt replacements.

- Larger stepper motors.

- Combined X/Y actuators. Threaded rod and pulley.

Structural

- Metal cast replacements for 3D printed brackets (particularly gantry 'boots').

Troubleshooting

When troubleshooting precision errors and planning upgrades, it is helpful to review the most likely causes.

- Inadequate or excessive wheel pressure (check eccentric spacers).

- Poor alignment along axes with multiple drivers.

- Twisting at or near linear motion carriages.

- Backlash at boots joining X and Z axes.

- Separation between highly stiff (table, 40 series extrusions) and less stiff (20 series extrusions) materials.

- Warping of stiff materials (should not ever occur, would imply gross overloading and abuse exceeding several hundred pounds force).

This category currently contains no pages or media.