Prusa Mendel Documentation: Difference between revisions

From HacDC Wiki

No edit summary |

|||

| Line 79: | Line 79: | ||

*If axes show signs of binding, wipe down rods with machine oil or oil the threaded rods. Be sure not to leave excess, that may lead to more build up. | *If axes show signs of binding, wipe down rods with machine oil or oil the threaded rods. Be sure not to leave excess, that may lead to more build up. | ||

*floss the hobbed bolt in the extruder | *floss the hobbed bolt in the extruder | ||

* wash the glass surface with water and soap. If using kapton/PET tape on the glass, wipe off with acetone | *wash the glass surface with water and soap. If using kapton/PET tape on the glass, wipe off with acetone | ||

*Z-axis level. Home the Z-axis, then move around X-axis. Extruder head should be about half a millimeter above the bed, but ABOVE the bed at all times. | |||

*Endstops. Make sure X/Y trigger properly by pushing them into the switches. Z-axis must position extruder ABOVE the bed at all times, not on it. | |||

=Operation= | =Operation= | ||

Revision as of 18:11, 24 September 2012

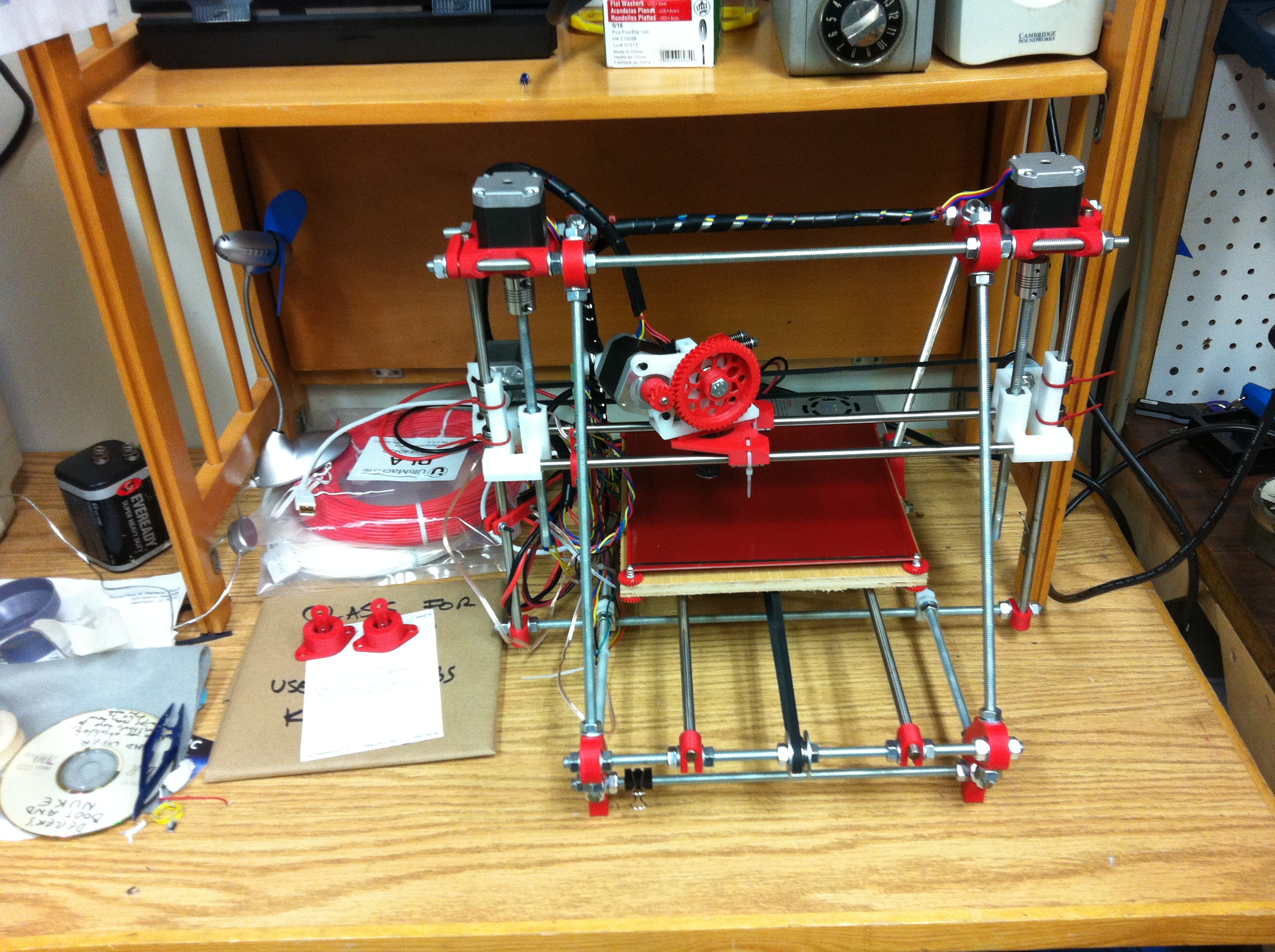

This is the page on how to use the newly built Prusa Mendel (iteration 2). A PC has been dedicated to run it, below you will find the toolchain used to run it and other details that you may find useful.

Current Machine Status

Operational

Workflow

CAD/Thingiverse -> Netfabb -> STL -> Slic3r -> Pronterface -> PRINT!

- CAD

- Any modelling software that can output the file format STL.

- Some programs of interest might be the following: Google Sketchup, OpenSCAD, TinkerCAD, Solid Works, AutoCAD, Rhino.

- And in case you don't want to model anything and simply want to print stuff, go to Thingiverse.

- Netfabb

- software for checking the "3D printability" of the model you created. Go to Netfabb and download the Studio Basic option. You can also simply use their cloud offering and have a repaired model emailed back to you.

- if your model has issues, run the repair function with default settings and see if that remedies the issues. The repair function can be used by clicking the "first aid" symbol found at the far right on the tool bar.

- STL

- current format for 3D printing (AMF is coming around the corner).

- at this point, your file should be patched up and ready to print.

- Slic3r

- software for creating 3d printing toolpaths

- precompiled binaries can be had from Slic3r.org or be built built from github.

- use the profiles already generated for best results.

- Pronterface

- GUI for controlling the Prusa.

- where you will connect to the printer, home, warm up and send print jobs from.

- can be built from github or download precompiled binaries for Windows/Mac here.

- preview G-Code generated by Slic3r.

- File is good to go, toolpaths are generated, time to let the robot do what it does best, PRINT!

Materials

- PLA

- ABS

- PLA

- Polylactic Acid

- made from corn starch, smells like waffles/syrup while printing

- less prone to warping

- more brittle compared to ABS

- needs a fan, it remains much more molten after being extruded

- lower operating temperatures (160C-200C)

- Preferred plastic of choice

- ABS

- same plastic in which LEGOs are made of

- flexible

- higher operating temps (220C-240C)

- smells like death, can release carcinogens at higher temps

- requires a heated bed (110C) or warping occurs

- requires kapton/PET tape on heated print surface for best adhesion. Possibly a light sanding of the surface and slurry of dissolved ABS in acetone for further warp prevention.

Machine Setup/Specs

This Prusa is fitted with the following:

- Melzi - loaded with the latest Marlin firmware (as of 9/1/2012)

- 12V 30A PSU

- Makergear 0.35mm for 3mm filament hot end

- LM8UUs

- GT2 (2mm) belting and pulleys (5mm bore, 20 tooth)

- 100K Thermistors (extruder an heated bed)

For FW reference on steps per axis: (80, 80, 2560, 666.67) {X, Y, Z, E}, this is also assuming 1/16th microstepping.

Maintenance

- Routinely check for loose wires

- If axes show signs of binding, wipe down rods with machine oil or oil the threaded rods. Be sure not to leave excess, that may lead to more build up.

- floss the hobbed bolt in the extruder

- wash the glass surface with water and soap. If using kapton/PET tape on the glass, wipe off with acetone

- Z-axis level. Home the Z-axis, then move around X-axis. Extruder head should be about half a millimeter above the bed, but ABOVE the bed at all times.

- Endstops. Make sure X/Y trigger properly by pushing them into the switches. Z-axis must position extruder ABOVE the bed at all times, not on it.

Operation

- Check for loose wires, you don't want anything shorting out or coming undone while printing

- Make sure that all endstops are lined up and will be triggered upon homing. Do so by manually pushing X/Y axes into their switches. For the Z axis, make sure nothing is obstructing its descent to the switch and that is at a safe distance where the hot-end will not crash into the print surface

- Check the print surface for any signs of fingerprints or residue that would prevent good adhesion. Clean if necessary.

- Ensure that the filament feed is not tangled and can freely unwind itself for the duration of the print.

- Assuming that you already have your STL file of choice either made from whatever CAD program you used or downloaded from Thingiverse, generate the G-Code via Slic3r (either using the profile already generated there or one that you customized).

- Depending on your file size/complexity, Slic3r can take awhile. Use this time to connect to the printer by opening the Printrun folder and running Pronterface.py (run in terminal when asked).

- If you are printing from a microSD, save the g-code file generated to the SD card and insert it into the SD port on the Melzi board. At this time, also switch the jumper for power selection from USB to the Vreg option. This will enable the board to be powered from the PSU instead of your laptop.

- Once open, connect to the printer. Make sure the baudrate is set to the 250000 and the correct port is selected, should read "...USB0". You will know when it is connected when it spits out some basic stats of the firmware loaded. Check the box that read "Monitor Printer," this will spit out current temp readings, make sure they are reasonable (~20C at room temp).

- Double check all wires for correct placement and secureness, you may now power on the PSU by turning on the power strip it is plugged into.

- Set your heated bed to 60C for PLA or 110C for ABS. Do not turn on the heater yet!

- Click "Load" and load the G-Code file you have created. A preview of the first layer should appear in the middle of Pronterface. You can click on the preview and walk through the layers by holding shift and scrolling on the trackpad. In the console, a time estimate for the print should also appear.

- At this point, you can turn on the heater. Set to 180C for PLA and 220C for ABS. Wait for it to hit temp and prime it. You can do this by either manually turning the large extruder gear or pressing the "Extrude" button. Do so until there is a nice and steady flow.

- Once all temps are hit and stable, file is loaded and extruder is primed...you can now hit print! If you are printing from SD, at this point you will click on the SD Print option, browse the SD card and select the file to run.

- Sit back and watch as the printer homes itself and sprints off to print your file!

To Do

- Tune trimpots on motor drivers

- Binder clips for glass surface

- Kapton tape for 2nd glass plate (for ABS)

- Acetone/Cotton balls (for cleaning Kapton surface)

- Spool System (mount printed Sky Hooks)

- Cable Management (Spiral wrap loose wires and ziptie down)