RepRap Operator's Log: Difference between revisions

From HacDC Wiki

Hexagon5un (talk | contribs) No edit summary |

Hexagon5un (talk | contribs) No edit summary |

||

| Line 1: | Line 1: | ||

When you use the RepRap, please add notes here. Newest at top. | When you use the RepRap, please add notes here. Newest at top. | ||

* Dec 20, 2010. (Elliot) A while ago, printed out a brutstruder head for the reprap. Assembled, installed, and tested it out last night, and it's a winner. Bought a new gearmotor to replace the old one which was slow and spineless. The thermistor is installed, but I haven't tweaked the relevant settings in the firmware, and not sure that I know how, so the hot end appears to be still running open-loop. This is no good. | * Dec 20, 2010. (Elliot) A while ago, printed out a brutstruder head for the reprap. [[Image:reprap_brutstruder.jpg]] Assembled, installed, and tested it out last night, and it's a winner. Bought a new gearmotor to replace the old one which was slow and spineless. The thermistor is installed, but I haven't tweaked the relevant settings in the firmware, and not sure that I know how, so the hot end appears to be still running open-loop. This is no good. | ||

* Nov 27, 2010. (Elliot) I finally got up the courage/stupidity to completely remove, disassemble, clean, and re-install the hot end on the reprap extruder. Photos and documentation are at [[Rebuilding the RepRap Hot End]]. The short version is that now it's nicely free-flowing and the extrusion speed is limited by the motor (slow!). I also added a 100k thermistor taped to the nozzle (a la makerbot) but I don't know how to re-integrate it into the machine. I also may have left too much of the insulation near the nozzle. If it tears/drags, feel free to trim it. | * Nov 27, 2010. (Elliot) I finally got up the courage/stupidity to completely remove, disassemble, clean, and re-install the hot end on the reprap extruder. Photos and documentation are at [[Rebuilding the RepRap Hot End]]. The short version is that now it's nicely free-flowing and the extrusion speed is limited by the motor (slow!). I also added a 100k thermistor taped to the nozzle (a la makerbot) but I don't know how to re-integrate it into the machine. I also may have left too much of the insulation near the nozzle. If it tears/drags, feel free to trim it. | ||

Revision as of 22:53, 21 December 2010

When you use the RepRap, please add notes here. Newest at top.

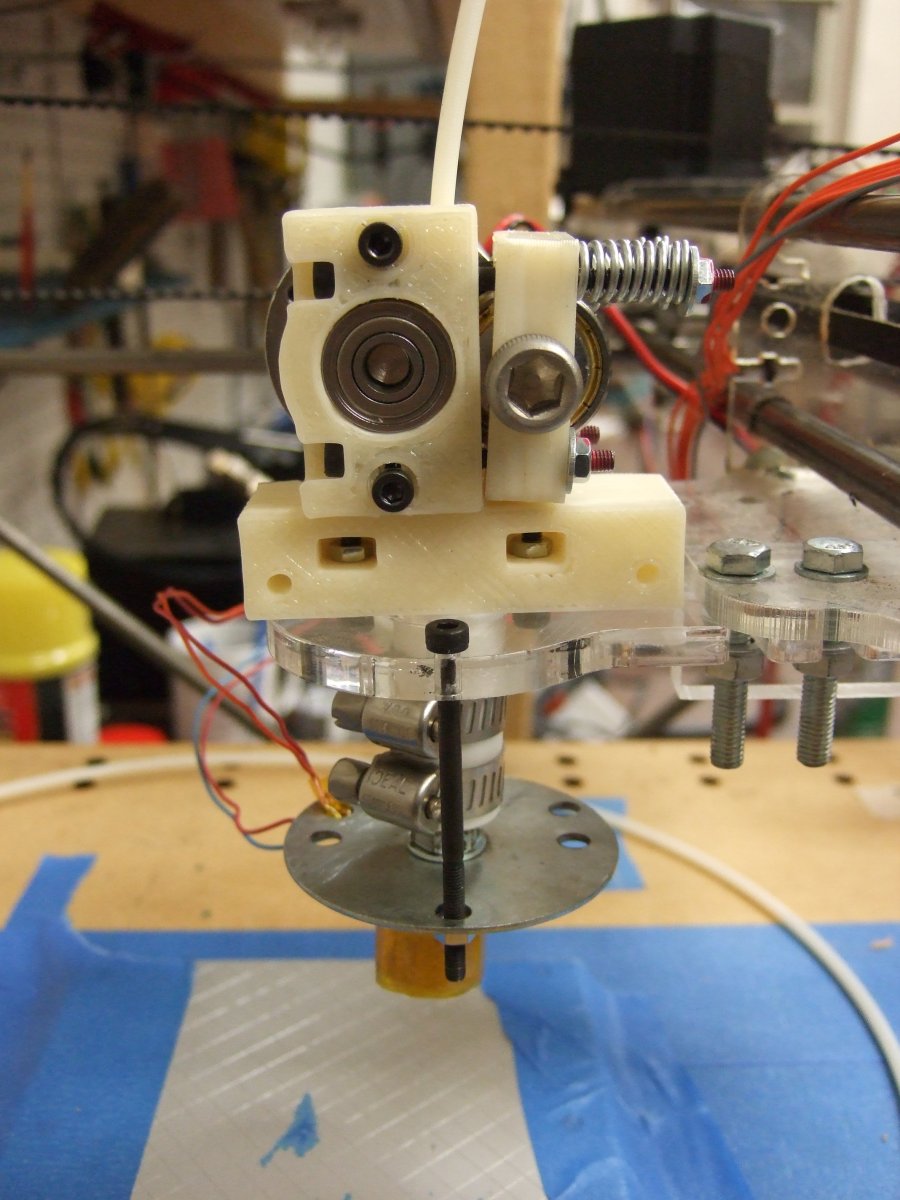

- Dec 20, 2010. (Elliot) A while ago, printed out a brutstruder head for the reprap.

Assembled, installed, and tested it out last night, and it's a winner. Bought a new gearmotor to replace the old one which was slow and spineless. The thermistor is installed, but I haven't tweaked the relevant settings in the firmware, and not sure that I know how, so the hot end appears to be still running open-loop. This is no good.

Assembled, installed, and tested it out last night, and it's a winner. Bought a new gearmotor to replace the old one which was slow and spineless. The thermistor is installed, but I haven't tweaked the relevant settings in the firmware, and not sure that I know how, so the hot end appears to be still running open-loop. This is no good.

- Nov 27, 2010. (Elliot) I finally got up the courage/stupidity to completely remove, disassemble, clean, and re-install the hot end on the reprap extruder. Photos and documentation are at Rebuilding the RepRap Hot End. The short version is that now it's nicely free-flowing and the extrusion speed is limited by the motor (slow!). I also added a 100k thermistor taped to the nozzle (a la makerbot) but I don't know how to re-integrate it into the machine. I also may have left too much of the insulation near the nozzle. If it tears/drags, feel free to trim it.