OpticalTableRobot: Difference between revisions

From HacDC Wiki

No edit summary |

No edit summary |

||

| Line 13: | Line 13: | ||

=Documentation= | =Documentation= | ||

Design hosted on [https://github.com/HacDC/OpticalTableRobot github]. | Design hosted on [https://github.com/HacDC/OpticalTableRobot github]. | ||

=Upgrades= | |||

Once the basic platform has been deployed, simple upgrades may be applied if necessary. These may be particularly relevant to edge cases like CNC milling or VLSI patterning. However, these upgrades involve tradeoffs (ie. inertia, friction, cost, etc), and should only be applied upon discovery of a clear requirement. | |||

==Relative Accuracy (Vibration)== | |||

* Multiple Z-Axis gantries. | |||

* Additional Z-axis actuators. | |||

* Z-axis threaded rod stabilizers. | |||

==Maximum Force== | |||

* Vectran rope timing belt replacements. | |||

* Larger stepper motors. | |||

* Combined X/Y actuators. Threaded rod and pulley. | |||

==Structural== | |||

* Metal cast replacements for 3D printed brackets (particularly gantry 'boots'). | |||

Revision as of 19:10, 4 September 2014

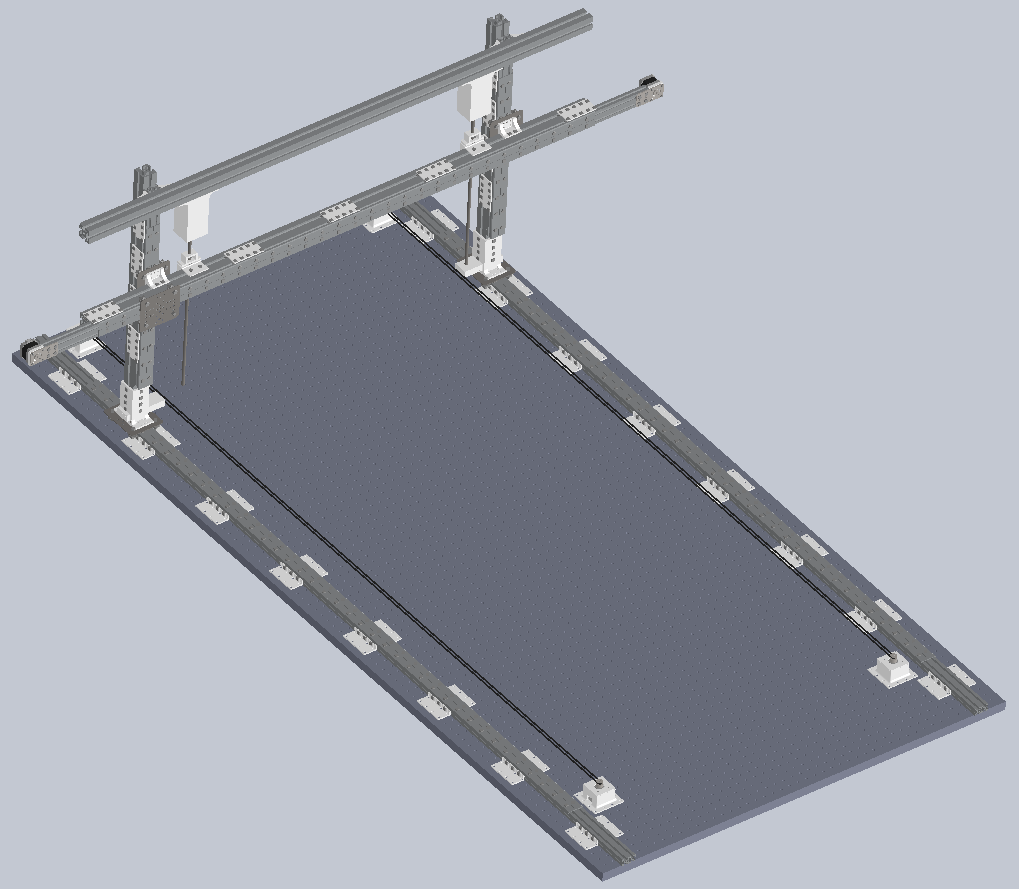

Multi-tool CNC platform in progress atop the optical table to enable ultra-precise fabrication on a massive scale. Derived from, and tool-compatible with, FlexReplicator.

This is the kind of machine one might use to 3D print large herringbone power transmissions for lost PLA casting, or carry out a VLSI production run.

Status

Funding available, design mostly complete, construction imminent.

Documentation

Design hosted on github.

Upgrades

Once the basic platform has been deployed, simple upgrades may be applied if necessary. These may be particularly relevant to edge cases like CNC milling or VLSI patterning. However, these upgrades involve tradeoffs (ie. inertia, friction, cost, etc), and should only be applied upon discovery of a clear requirement.

Relative Accuracy (Vibration)

- Multiple Z-Axis gantries.

- Additional Z-axis actuators.

- Z-axis threaded rod stabilizers.

Maximum Force

- Vectran rope timing belt replacements.

- Larger stepper motors.

- Combined X/Y actuators. Threaded rod and pulley.

Structural

- Metal cast replacements for 3D printed brackets (particularly gantry 'boots').