Photolithography PCB Fab: Difference between revisions

From HacDC Wiki

No edit summary |

No edit summary |

||

| Line 1: | Line 1: | ||

[[Category:Equipment]] | [[Category:Equipment]] | ||

[[File:PCB_Photoexposure_Jig.jpg|500px|right]] | |||

When the 10mil isolation paths offered by CNC Milling are insufficient, photolithography becomes the PCB fabrication method of choice. | When the 10mil isolation paths offered by CNC Milling are insufficient, photolithography becomes the PCB fabrication method of choice. | ||

=PCB Design= | |||

Recommend gEDA. Project template with CNC Mill and gerber export scripts available on [https://github.com/mirage335/gEDA_Template github]. | |||

=Process= | |||

Simple, consisting of: | |||

# Photosensitive copper clad board. If not already available, more can be made by laminating dry film photoresist to bare copper clad board. | |||

# Via/hole drilling, outline milling, etc. Best done automatically on CNC mill. | |||

# Photomask. Printed on transparencies at high-resolution. Some laser printers may require double layer photomasks. Alternatively, <445nm lasers may be able to selectively expose the photoresist. | |||

# UV exposure. Sunlight or high-brightness CFL bulbs can expose the photoresist in ~30 minutes. | |||

# Development. Use a foam brush with the appropriate developer solution from the chemicals shelf. | |||

# Etching. Copper etchant acid solution removes exposed copper. | |||

# Striping. Sodium hydroxide completely removes photoresist. May need additional UV exposure. | |||

# Solder mask. Optional. Laminate two dry film photoresist sheets onto the PCB, apply photomask, expose, and develop. Alternatively, laser cut a negative solder mask from blue tape, and apply high-temperature spraypaint. | |||

=Assembly= | |||

For large boards with hundreds of components, reflow can be quicker than manual soldering. | |||

# Laser cut solder paste stencil from blue tape. Apply stencil to PCB. | |||

# Add smooth, paper thin layer of solder paste with a razor. | |||

# Remove stencil. | |||

# Place components on the appropriate pads. | |||

# Carefully melt the solder with the hot-air reflow tool. Hold the hot-air tool close to the components at 400C and maximum airflow, watch carefully, and progressively move the tool across the board as solder melts. | |||

=Resources= | |||

HacDC has the requisite resources: | |||

* Laser printer. | |||

* Transparencies. | |||

* Photosensitive copper clad board. | |||

* Dry film photoresist. | |||

* Various photodeveloper chemicals. | |||

* Copper dissolving etchant. | |||

* CNC Mill. | |||

=Demo= | |||

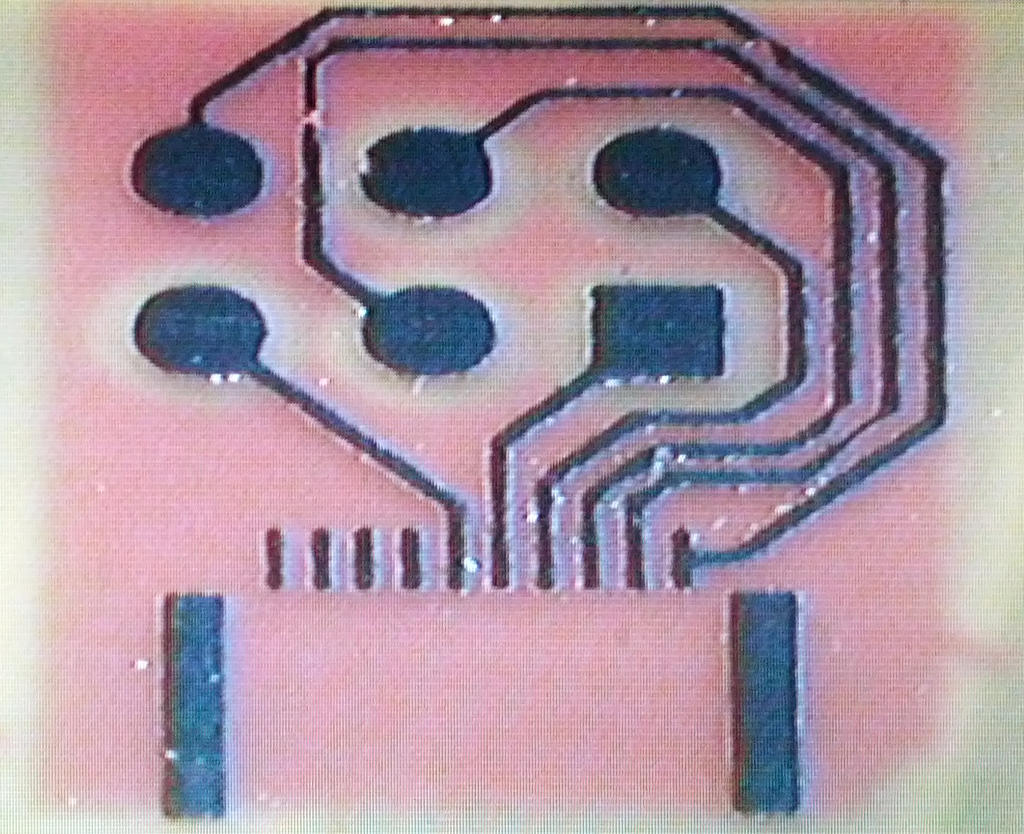

Chemically developed and etched PCB. Photomask remaining. | |||

[[File:DevelopedEtched.jpg|500px]] | |||

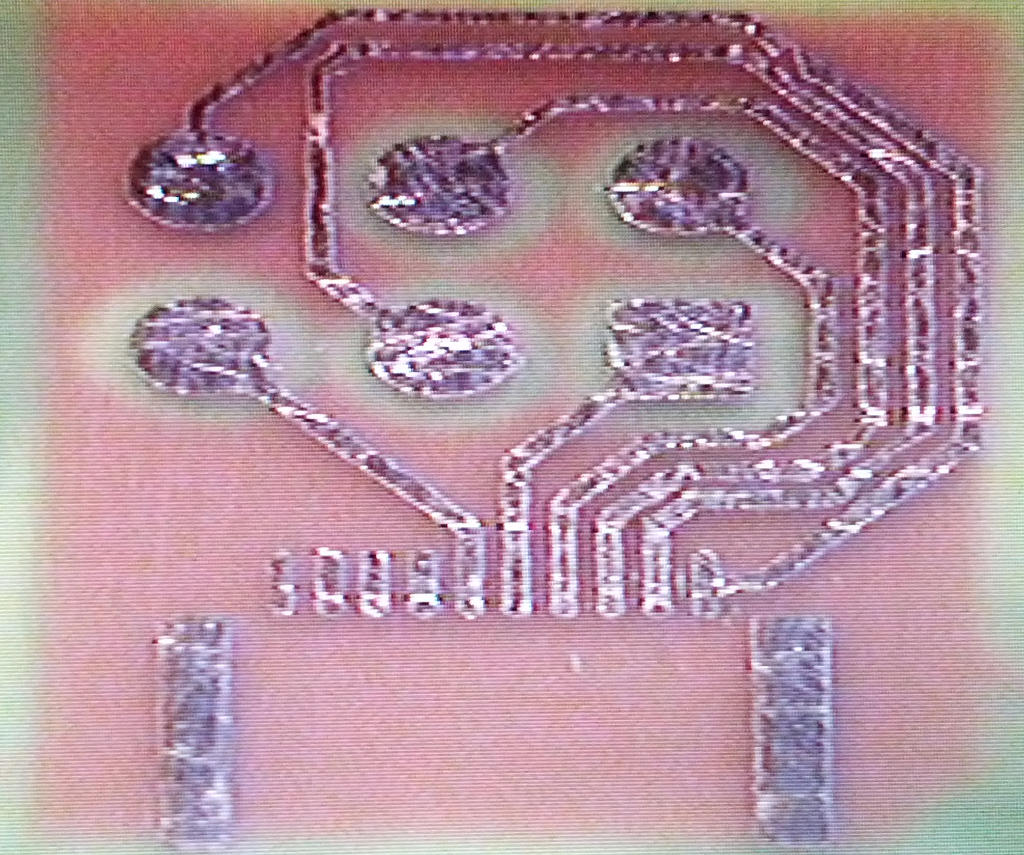

Photomask stripped, bare copper PCB electrically tested. | |||

[[File:DevelopedEtchedStrippedTested.jpg|500px]] | |||

Aligned reverse side. | |||

[[File:DevelopedEtchedStrippedTested_Reverse.jpg|500px]] | |||

=Reference= | =Reference= | ||

http://www.instructables.com/id/Killer-PCBs/ | http://www.instructables.com/id/Killer-PCBs/ | ||

http://www.mgchemicals.com/downloads/pdf/negativePrototyping.pdf | http://www.mgchemicals.com/downloads/pdf/negativePrototyping.pdf | ||

Revision as of 20:47, 27 January 2014

When the 10mil isolation paths offered by CNC Milling are insufficient, photolithography becomes the PCB fabrication method of choice.

PCB Design

Recommend gEDA. Project template with CNC Mill and gerber export scripts available on github.

Process

Simple, consisting of:

- Photosensitive copper clad board. If not already available, more can be made by laminating dry film photoresist to bare copper clad board.

- Via/hole drilling, outline milling, etc. Best done automatically on CNC mill.

- Photomask. Printed on transparencies at high-resolution. Some laser printers may require double layer photomasks. Alternatively, <445nm lasers may be able to selectively expose the photoresist.

- UV exposure. Sunlight or high-brightness CFL bulbs can expose the photoresist in ~30 minutes.

- Development. Use a foam brush with the appropriate developer solution from the chemicals shelf.

- Etching. Copper etchant acid solution removes exposed copper.

- Striping. Sodium hydroxide completely removes photoresist. May need additional UV exposure.

- Solder mask. Optional. Laminate two dry film photoresist sheets onto the PCB, apply photomask, expose, and develop. Alternatively, laser cut a negative solder mask from blue tape, and apply high-temperature spraypaint.

Assembly

For large boards with hundreds of components, reflow can be quicker than manual soldering.

- Laser cut solder paste stencil from blue tape. Apply stencil to PCB.

- Add smooth, paper thin layer of solder paste with a razor.

- Remove stencil.

- Place components on the appropriate pads.

- Carefully melt the solder with the hot-air reflow tool. Hold the hot-air tool close to the components at 400C and maximum airflow, watch carefully, and progressively move the tool across the board as solder melts.

Resources

HacDC has the requisite resources:

- Laser printer.

- Transparencies.

- Photosensitive copper clad board.

- Dry film photoresist.

- Various photodeveloper chemicals.

- Copper dissolving etchant.

- CNC Mill.

Demo

Chemically developed and etched PCB. Photomask remaining.

Photomask stripped, bare copper PCB electrically tested.

Reference

http://www.instructables.com/id/Killer-PCBs/ http://www.mgchemicals.com/downloads/pdf/negativePrototyping.pdf