F3-robot: Difference between revisions

From HacDC Wiki

No edit summary |

(trying to move to Previous Projects) |

||

| (15 intermediate revisions by one other user not shown) | |||

| Line 1: | Line 1: | ||

David Whiteis has | David Whiteis has loaned the '''CRS/Fisher F3 Robotic arm''' to Dr. Nuno Martin's group at the University of Maryland. | ||

HacDC members interested in working with the robot should get in touch with David. | |||

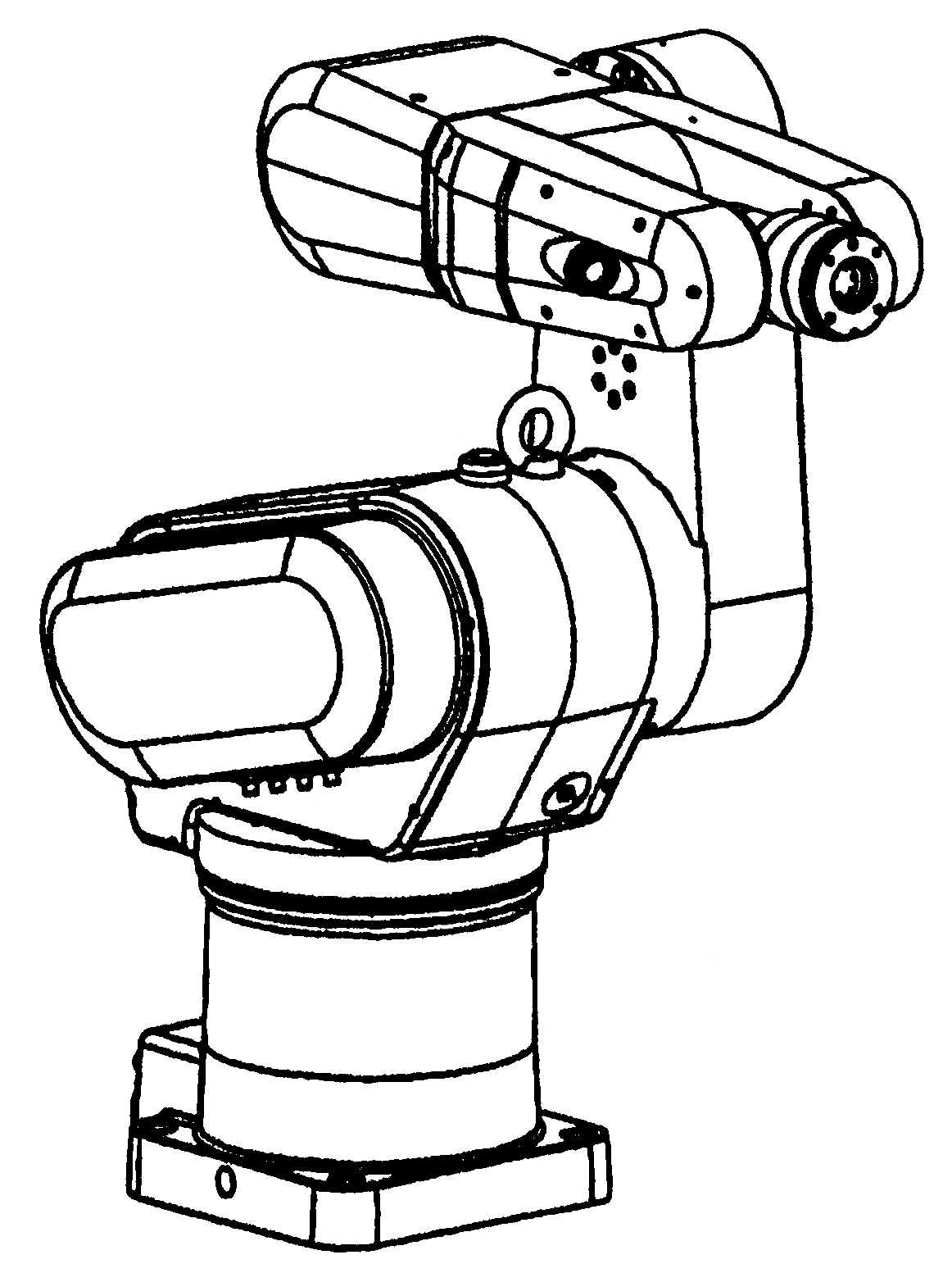

[[File:f3-robot-drawing-edited.jpg|200px|thumb|left|CRS F3 Robotic Arm]] | |||

'''We are currently gathering ideas about what we might do with the robot. Here is part of what we have come up with so far, shown in groups and including sample videos where possible.''' | |||

We may use this wiki page to document what we have learned about the robot, what projects are proposed, planned or implemented, and more videos of the machine in action. | |||

== Moving and stacking stuff: == | |||

Grabbing dominoes from a stack, setting them up to tumble over in a row: http://www.youtube.com/watch?v=-UzOfwHeV5k | |||

== Videoing stuff: == | |||

Holding a video camera in the gripper, and filming while in motion: http://www.youtube.com/watch?v=2GDsFChduiI | |||

That second video gives a limited overview of the robot's ability as an advanced 3D video camera dolly. We know a lot more about what is possible now. You could make some amazing videos with that setup. Here are some of the lessons learned: | |||

- Videoing miniatures such as model train layouts is fun and gives great results. | |||

- Get in close, and don't pan too much. | |||

- Keep a single object as the center of focus, and change the camera location while keeping that focus. | |||

- Track moving objects making complex movements, like a model train following a track. | |||

The O scale train in the above video was good, but tracking a smaller train (HO or N scale) would be much better, since then the robot could track the train through multiple left and right turns, much like a real-world helicopter filming a train for a Hollywood movie. | |||

David plans to reach out to model train enthusiasts to see if there is interest in collaborating on a movie that really shows off the technology. | |||

David sent an email on 3-8-13 to '[email protected]' to see if the film school students at http://www.marylandfilmmakersclub.com/home.html are interested in collaborating on a project. | |||

You could do great stop-motion animation with the setup. Your camera could move slightly every time your parts/clay are moved, making for a much more dynamic and flowing movie than when the camera stays in a static position. | |||

If you programmed the arm to move the camera through the air in a big, elaborate flowing path, and then had someone who was a hotshot at flying miniature RC helicopters fly a pattern that kept it in front of the lens, that would make an amazing video. | |||

== 3D printing, or subtractive CNC machining: == | |||

We have talked about mounting a plastic extruder, Dremel router, or cutting laser on the tool post, but we have not done any of this yet. Will it be you that drives this project? | |||

== | == More on Maker Tech Tuesdays: == | ||

For several months the F3 robot was at Chas Colburn's place, before it was loaned to the University of Maryland. | |||

Maker Tech Tuesdays is a hackerspace provided by Chas Colburn at his place of business, 3DMetalParts, just south of the University of Maryland. The space is free to visit and is open every Tuesday. | |||

Chas & Maker Tech Tuesday's Facebook page: | Chas & Maker Tech Tuesday's Facebook page: | ||

| Line 21: | Line 49: | ||

More info on Chas is here, search for 'Colburn': | More info on Chas is here, search for 'Colburn': | ||

http://wiki.hacdc.org/index.php/Suppliers | http://wiki.hacdc.org/index.php/Suppliers | ||

[[Category:Previous_Projects]] | |||

Latest revision as of 03:18, 16 December 2016

David Whiteis has loaned the CRS/Fisher F3 Robotic arm to Dr. Nuno Martin's group at the University of Maryland.

HacDC members interested in working with the robot should get in touch with David.

We are currently gathering ideas about what we might do with the robot. Here is part of what we have come up with so far, shown in groups and including sample videos where possible.

We may use this wiki page to document what we have learned about the robot, what projects are proposed, planned or implemented, and more videos of the machine in action.

Moving and stacking stuff:

Grabbing dominoes from a stack, setting them up to tumble over in a row: http://www.youtube.com/watch?v=-UzOfwHeV5k

Videoing stuff:

Holding a video camera in the gripper, and filming while in motion: http://www.youtube.com/watch?v=2GDsFChduiI That second video gives a limited overview of the robot's ability as an advanced 3D video camera dolly. We know a lot more about what is possible now. You could make some amazing videos with that setup. Here are some of the lessons learned:

- Videoing miniatures such as model train layouts is fun and gives great results. - Get in close, and don't pan too much. - Keep a single object as the center of focus, and change the camera location while keeping that focus. - Track moving objects making complex movements, like a model train following a track.

The O scale train in the above video was good, but tracking a smaller train (HO or N scale) would be much better, since then the robot could track the train through multiple left and right turns, much like a real-world helicopter filming a train for a Hollywood movie.

David plans to reach out to model train enthusiasts to see if there is interest in collaborating on a movie that really shows off the technology.

David sent an email on 3-8-13 to '[email protected]' to see if the film school students at http://www.marylandfilmmakersclub.com/home.html are interested in collaborating on a project.

You could do great stop-motion animation with the setup. Your camera could move slightly every time your parts/clay are moved, making for a much more dynamic and flowing movie than when the camera stays in a static position.

If you programmed the arm to move the camera through the air in a big, elaborate flowing path, and then had someone who was a hotshot at flying miniature RC helicopters fly a pattern that kept it in front of the lens, that would make an amazing video.

3D printing, or subtractive CNC machining:

We have talked about mounting a plastic extruder, Dremel router, or cutting laser on the tool post, but we have not done any of this yet. Will it be you that drives this project?

More on Maker Tech Tuesdays:

For several months the F3 robot was at Chas Colburn's place, before it was loaned to the University of Maryland.

Maker Tech Tuesdays is a hackerspace provided by Chas Colburn at his place of business, 3DMetalParts, just south of the University of Maryland. The space is free to visit and is open every Tuesday.

Chas & Maker Tech Tuesday's Facebook page: http://www.facebook.com/video/video.php?v=10150900147128842

More info on Chas is here, search for 'Colburn': http://wiki.hacdc.org/index.php/Suppliers