CNC Mill: Difference between revisions

From HacDC Wiki

(→Quickstart: included program opening) |

(→Quickstart: updated to include info regarding killswitch.) |

||

| Line 10: | Line 10: | ||

# MDI tab in Mach3 allows manual G-Code entry. This is useful for commanding the mill to specific locations (eg. g0 x0 y0 z5) . | # MDI tab in Mach3 allows manual G-Code entry. This is useful for commanding the mill to specific locations (eg. g0 x0 y0 z5) . | ||

# Gently change mill bits with crescent wrenches. Finger tight is often sufficient. | # Gently change mill bits with crescent wrenches. Finger tight is often sufficient. | ||

#If, for some reason, you need to turn offof the CNC mill while it's milling, a kill switch had been added to eliminate the need to stick ones hand in hazardous places. The killswitch is circled in red in the image to the right. | |||

=Cleanup= | =Cleanup= | ||

Revision as of 22:03, 5 March 2016

Quickstart

- Turn on dedicated desktop computer. Mach3 is available under MS Windows.

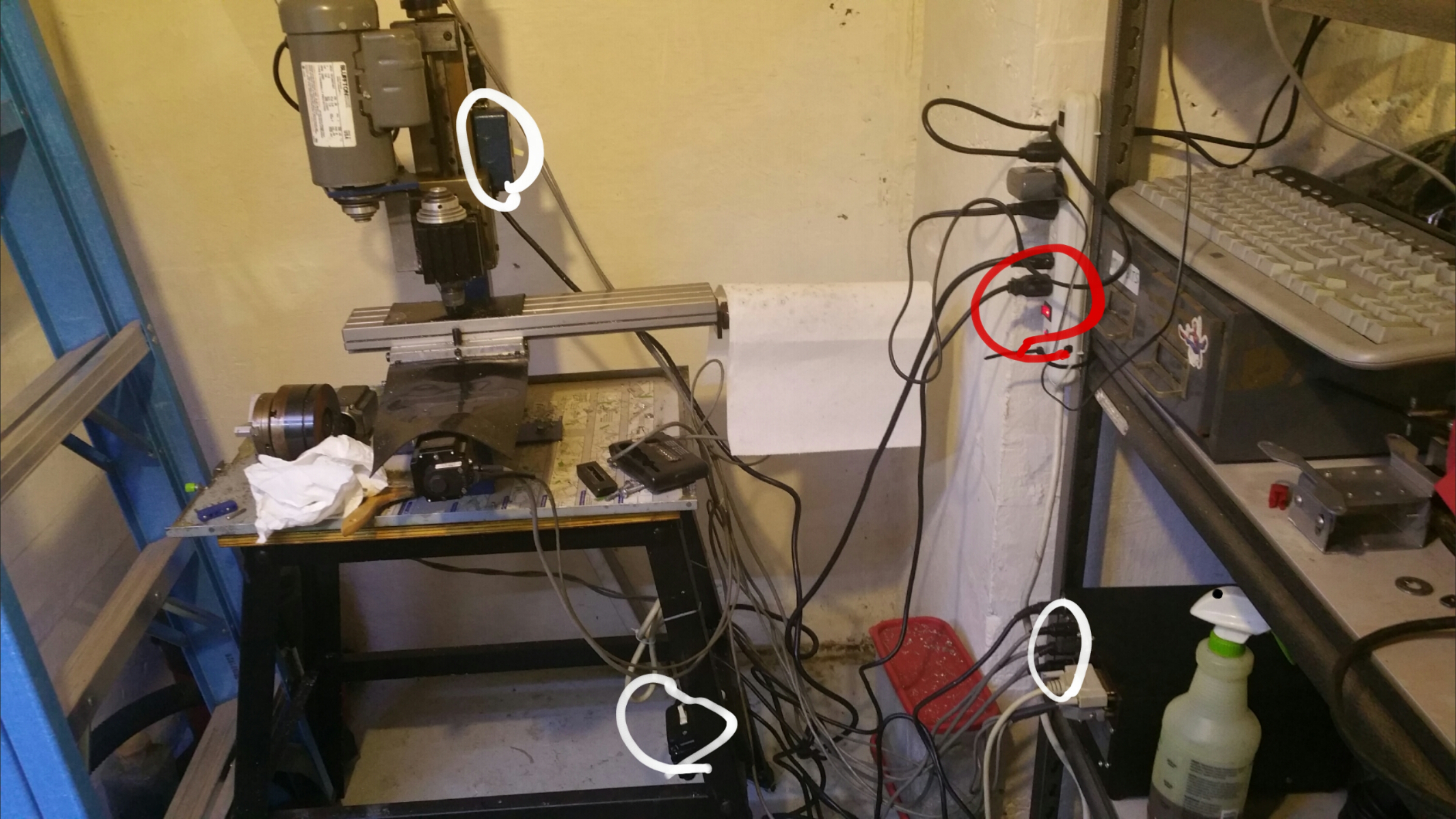

- Turn on all three lightswitches: back of the "MicroProto Systems, MicroMill DSLS 3000" box, top of the M3/M5 box, and to the side of the mill spindle. (Switches are circled in white in the image to the right)

- Double click the desktop shortcut "CNC_mill" to open software. "Tab" key brings up the jog controls.

- MDI tab in Mach3 allows manual G-Code entry. This is useful for commanding the mill to specific locations (eg. g0 x0 y0 z5) .

- Gently change mill bits with crescent wrenches. Finger tight is often sufficient.

- If, for some reason, you need to turn offof the CNC mill while it's milling, a kill switch had been added to eliminate the need to stick ones hand in hazardous places. The killswitch is circled in red in the image to the right.

Cleanup

- Turn off all three power switches noted above.

- Shutdown dedicated computer.

- Please cleanup the mill area and place tooling back into the mill toolbox under the bench.

Please Avoid

- Obviously, don't put your hands in hazardous places.

- Stay with the mill unless you really know what _all_ the risks are. Strange things can happen, particularly "dig-in" and g-code misinterpretation.

- Milling the mill itself (or our mounting hardware) is easily possible, and a rather expensive mistake.

- Use G91.1 with certain automatically generated G-Code files (eg. pcb2gcode, solidcam). Mach3 seems to default to absolute arc/circle center coordinates which catastrophically enlarges the arcs/circles.

Otherwise, the mill is robust and newbie friendly.

Pages in category "CNC Mill"

The following 4 pages are in this category, out of 4 total.