OpticalTableRobot: Difference between revisions

From HacDC Wiki

(Tool statuses.) |

(Locate source of the 3d printed parts.) |

||

| (20 intermediate revisions by 2 users not shown) | |||

| Line 4: | Line 4: | ||

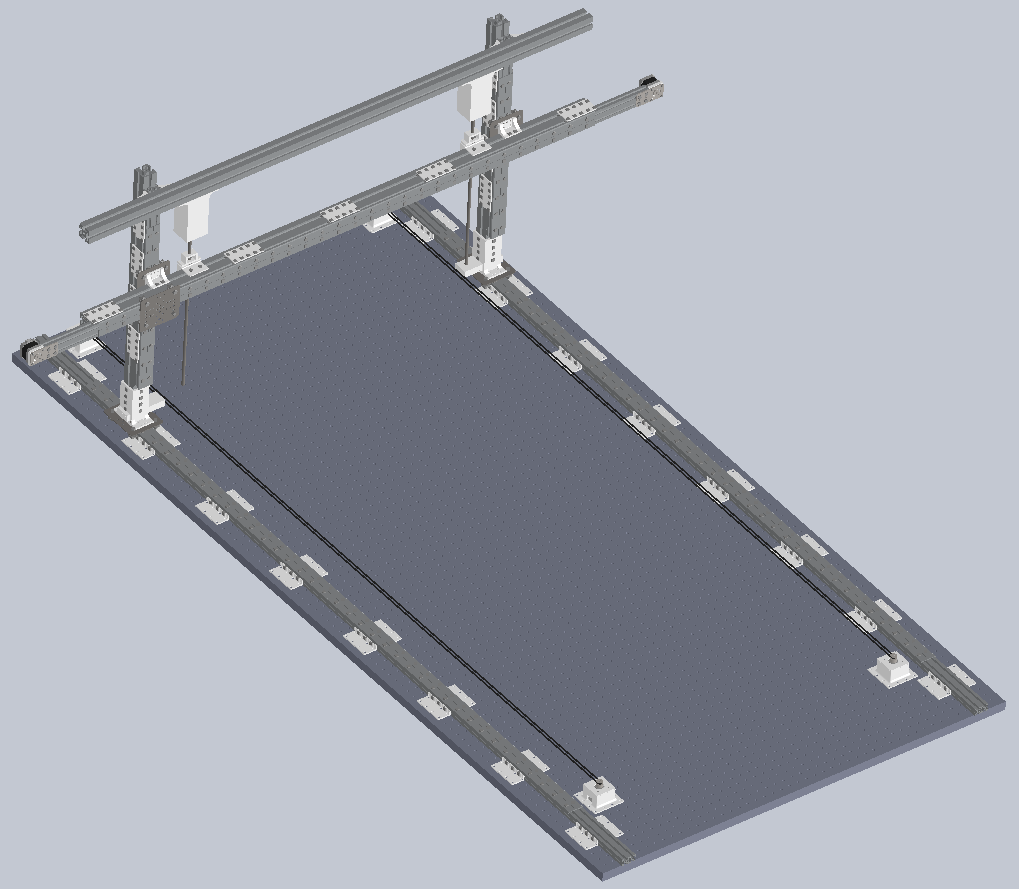

[[File:OpticalTableRobot.png|400px|right]] | [[File:OpticalTableRobot.png|400px|right]] | ||

Multi-tool CNC platform in progress atop the optical table to enable ultra-precise fabrication on a massive scale. Derived from | Multi-tool CNC platform in progress atop the optical table to enable ultra-precise fabrication on a massive scale. Derived from [https://github.com/mirage335/FlexReplicator FlexReplicator]. Tool compatible with [https://github.com/mirage335/FlexReplicator FlexReplicator], [https://github.com/mirage335/Taz_Mega TazMega], [https://github.com/mirage335/TazStiff TazStiff], [https://github.com/mirage335/MightyTool MightyTool], and related projects. | ||

This is the kind of machine one might use to 3D print large herringbone power transmissions for lost PLA casting, or carry out a VLSI production run. | This is the kind of machine one might use to laser cut giant tractor parts, 3D print large herringbone power transmissions for lost PLA casting, or carry out a VLSI production run. Or of course, typical laser paper cutting. | ||

=Status= | =Status= | ||

| Line 13: | Line 13: | ||

=Features= | =Features= | ||

* Approximately 7'x2'x1.5' build area. | * Approximately 7'x2'x1.5' build area. | ||

* Built on 100W Laser Cutter (tube down ATM) | * Built on 100W Laser Cutter (tube down ATM). | ||

* Rock-solid, supported by | * Rock-solid, supported by optical table and 40 series extrusions. | ||

* Supports multiple tools and capabilities, | * Supports multiple tools and capabilities, starting with 3D printing and Laser Cutting. | ||

* Simultaneous multi-tool use will enhance | * Simultaneous multi-tool use will enhance utility, such as milling down 3D printed layers. | ||

=Hardware= | |||

* Part of design hosted on [https://github.com/HacDC/OpticalTableRobot github]. | * Part of design hosted on [https://github.com/HacDC/OpticalTableRobot github]. | ||

* Rest of design hosted at [http://fosscar.faikvm.com/trac/wiki/LargePrinter The FossCar Project]. | * Rest of design hosted at [http://fosscar.faikvm.com/trac/wiki/LargePrinter The FossCar Project]. | ||

* 3D printed parts are hosted at [http://kalli1.faikvm.com/HacDC/OpticalTableRobot/files/tip/ Julia Longtin's Kallithea instance]. | |||

The microcontroller we are using is a RAMBO board. | |||

=Software= | |||

==User Interface== | |||

We are using Pronterface and Pronsole from the PrintRun package. | |||

I am taking PNG snapshots of STL files using [https://github.com/jhdulaney/stltools A Customized STLTools]. | |||

==Embedded Controller== | |||

The Optical Table robot is running [https://github.com/MarlinFirmware/Marlin The Marlin Firmware]. | |||

For laser cutting purposes, we need to merge what is running on the machine with [https://github.com/lansing-makers-network/buildlog-lasercutter-marlin The K40 Firmware]. | |||

===Issues=== | |||

Note that these issues are with the current Marlin Firmware. (FIXME: which version?) | |||

* Y minimum endstop not functional. | |||

* Uptime of around 4-6 hours. | |||

==3D Printing== | |||

For slicing 3d printable objects, We are using [https://github.com/alexrj/Slic3r Slic3r]. | |||

For object design, we are using [https://github.com/colah/ImplicitCAD/ ImplicitCAD]. | |||

==Laser Cutting== | |||

For designing cut out parts, we are moving to using [https://github.com/colah/ImplicitCAD/ ImplicitCAD]. | |||

=Tools= | =Tools= | ||

==IR Laser== | ==IR Laser== | ||

Tested. Mirrors are in place, but laser tube has died. | Tested. Mirrors are in place, but laser tube has died. | ||

== | ==Extruders== | ||

In | In progress. Works just like any other 3D printer. Plan on at least two nozzles, one for high-precision (<0.35mm), one for high-speed (>1mm). | ||

==Mill== | ==Mill== | ||

In progress. Standard 120V AC drill, connected to control circuitry by SSR. | In progress. Standard 120V AC drill, connected to control circuitry by SSR. | ||

==Pick And Place== | |||

In Progress. camera system, part feeders, and vacuum based pick up and rotate tool will need to be added. | |||

==Liquid Deposition== | |||

In Progress. Epson piezoelectric print heads are useful for this. | |||

==VLSI Projection Lithography== | ==VLSI Projection Lithography== | ||

In progress. Modified (ultraviolet) DLP projector and camera mounted to microscope, used for high-resolution patterning. Absolute accuracy (inter-frame) is expected to be ~2um, while relative accuracy (intra-frame) is expected to be <0.5um, scalable down to diffraction-limited performance. | In progress. Modified (ultraviolet) DLP projector and camera mounted to microscope, used for high-resolution patterning. Absolute accuracy (inter-frame) is expected to be ~2um, while relative accuracy (intra-frame) is expected to be <0.5um, scalable down to diffraction-limited performance. | ||

=Casting= | =Processes= | ||

==Casting== | |||

Direct metal printing thus far is either highly expensive, low-strength, or both. Compromise is to 3D print a plastic (PLA) part, then cast it to metal. Besides low cost, this process can be used to achieve parts traditionally infeasible, like pre-assembled herringbone-gear power transmissions. | Direct metal printing thus far is either highly expensive, low-strength, or both. Compromise is to 3D print a plastic (PLA) part, then cast it to metal. Besides low cost, this process can be used to achieve parts traditionally infeasible, like pre-assembled herringbone-gear power transmissions. | ||

=Pricing= | =Pricing= | ||

As with other HacDC tools, operators are asked to pay for consumables used only for heavy usage. However, this machine can easily consume | As with other HacDC tools, operators are asked to pay for consumables used only for heavy usage. However, this machine can easily consume a few hundred dollars of filament in one job... | ||

=Safety= | =Safety= | ||

Usual safety precautions apply. | Usual safety precautions apply. | ||

ClassIV lasers can typically cause catastrophic retina damage will instantly upon viewing the projected spot. Ideally, a 'defense-in-depth' approach should be taken combining safety glasses and guards at all times. | |||

Somewhat less true of CO2 lasers, as the far-infrared wavelength cannot be focused by the lens in human eyes. Nonetheless, polycarbonate safety glasses should be used, and walls should be in place to keep the collimated beam on the table. | |||

= | =TODO= | ||

# Fix the policy around the HacDC basement, so volunteers can work with less politics. | |||

# Replace the laser tube. Maybe try a cheap, expendable tube for the first few hundred hours. | |||

# Find out why the microcontroller locks up when firing up the laser every 3-4 hours. | |||

# Trim the Z threaded rods. | |||

## these need trimmed, while on the machine, until the end is at exactly the height of the bottom of the connecting bar, on the top of the gantry. | |||

# Print new X ends. | |||

# Print a more adjustable Z endstop. | |||

# Place the electronics in an enclosure. | |||

# make the display unit function. | |||

# Add cable chains. | |||

==Upgrades== | |||

For absolute maximum performance, consider the following upgrades. | |||

* Interferometric linear optical encoders. | * Interferometric linear optical encoders. | ||

* | * Vectran rope timing belt replacements. | ||

* Angle iron brackets reinforced by welded plate. | |||

== | ==Saftey== | ||

# Add walls, to keep the collimated beam on the table. | |||

# Add a polycarbonate lid. | |||

# Add an exhaust system. | |||

== | ==Usability== | ||

# Add OctoPi or similar web interface. | |||

=Troubleshooting= | |||

When troubleshooting precision errors and planning upgrades, it is helpful to review the most likely causes. | When troubleshooting precision errors and planning upgrades, it is helpful to review the most likely causes. | ||

Latest revision as of 19:48, 30 January 2016

Multi-tool CNC platform in progress atop the optical table to enable ultra-precise fabrication on a massive scale. Derived from FlexReplicator. Tool compatible with FlexReplicator, TazMega, TazStiff, MightyTool, and related projects.

This is the kind of machine one might use to laser cut giant tractor parts, 3D print large herringbone power transmissions for lost PLA casting, or carry out a VLSI production run. Or of course, typical laser paper cutting.

Status

Assembled and operational.

Features

- Approximately 7'x2'x1.5' build area.

- Built on 100W Laser Cutter (tube down ATM).

- Rock-solid, supported by optical table and 40 series extrusions.

- Supports multiple tools and capabilities, starting with 3D printing and Laser Cutting.

- Simultaneous multi-tool use will enhance utility, such as milling down 3D printed layers.

Hardware

- Part of design hosted on github.

- Rest of design hosted at The FossCar Project.

- 3D printed parts are hosted at Julia Longtin's Kallithea instance.

The microcontroller we are using is a RAMBO board.

Software

User Interface

We are using Pronterface and Pronsole from the PrintRun package.

I am taking PNG snapshots of STL files using A Customized STLTools.

Embedded Controller

The Optical Table robot is running The Marlin Firmware.

For laser cutting purposes, we need to merge what is running on the machine with The K40 Firmware.

Issues

Note that these issues are with the current Marlin Firmware. (FIXME: which version?)

- Y minimum endstop not functional.

- Uptime of around 4-6 hours.

3D Printing

For slicing 3d printable objects, We are using Slic3r.

For object design, we are using ImplicitCAD.

Laser Cutting

For designing cut out parts, we are moving to using ImplicitCAD.

Tools

IR Laser

Tested. Mirrors are in place, but laser tube has died.

Extruders

In progress. Works just like any other 3D printer. Plan on at least two nozzles, one for high-precision (<0.35mm), one for high-speed (>1mm).

Mill

In progress. Standard 120V AC drill, connected to control circuitry by SSR.

Pick And Place

In Progress. camera system, part feeders, and vacuum based pick up and rotate tool will need to be added.

Liquid Deposition

In Progress. Epson piezoelectric print heads are useful for this.

VLSI Projection Lithography

In progress. Modified (ultraviolet) DLP projector and camera mounted to microscope, used for high-resolution patterning. Absolute accuracy (inter-frame) is expected to be ~2um, while relative accuracy (intra-frame) is expected to be <0.5um, scalable down to diffraction-limited performance.

Processes

Casting

Direct metal printing thus far is either highly expensive, low-strength, or both. Compromise is to 3D print a plastic (PLA) part, then cast it to metal. Besides low cost, this process can be used to achieve parts traditionally infeasible, like pre-assembled herringbone-gear power transmissions.

Pricing

As with other HacDC tools, operators are asked to pay for consumables used only for heavy usage. However, this machine can easily consume a few hundred dollars of filament in one job...

Safety

Usual safety precautions apply.

ClassIV lasers can typically cause catastrophic retina damage will instantly upon viewing the projected spot. Ideally, a 'defense-in-depth' approach should be taken combining safety glasses and guards at all times.

Somewhat less true of CO2 lasers, as the far-infrared wavelength cannot be focused by the lens in human eyes. Nonetheless, polycarbonate safety glasses should be used, and walls should be in place to keep the collimated beam on the table.

TODO

- Fix the policy around the HacDC basement, so volunteers can work with less politics.

- Replace the laser tube. Maybe try a cheap, expendable tube for the first few hundred hours.

- Find out why the microcontroller locks up when firing up the laser every 3-4 hours.

- Trim the Z threaded rods.

- these need trimmed, while on the machine, until the end is at exactly the height of the bottom of the connecting bar, on the top of the gantry.

- Print new X ends.

- Print a more adjustable Z endstop.

- Place the electronics in an enclosure.

- make the display unit function.

- Add cable chains.

Upgrades

For absolute maximum performance, consider the following upgrades.

- Interferometric linear optical encoders.

- Vectran rope timing belt replacements.

- Angle iron brackets reinforced by welded plate.

Saftey

- Add walls, to keep the collimated beam on the table.

- Add a polycarbonate lid.

- Add an exhaust system.

Usability

- Add OctoPi or similar web interface.

Troubleshooting

When troubleshooting precision errors and planning upgrades, it is helpful to review the most likely causes.

- Inadequate or excessive wheel pressure (check eccentric spacers).

- Poor alignment along axes with multiple drivers.

- Twisting at or near linear motion carriages.

- Backlash at boots joining X and Z axes.

- Separation between highly stiff (table, 40 series extrusions) and less stiff (20 series extrusions) materials.

- Warping of stiff materials (should not ever occur, would imply gross overloading and abuse exceeding several hundred pounds force).

This category currently contains no pages or media.